Industrial wastewater is one of the most pressing environmental and operational challenges faced by modern industries. Whether it comes from manufacturing facilities, food processing plants, or pharmaceutical operations, wastewater streams often carry high concentrations of suspended solids, organic matter, and unwanted metals. Left untreated, these pollutants can compromise water bodies, damage ecosystems, and put facilities at risk of noncompliance with federal regulations. As a result, wastewater treatment has become not just a regulatory necessity but also a critical component of sustainable industrial operations.

Among the many approaches used in industrial wastewater treatment, coagulation methods have consistently proven to be among the most effective. Coagulation is one of the oldest yet most adaptable chemical treatment strategies, designed to destabilize fine particles and organic materials suspended in water. Through the addition of coagulant chemicals, charged particles are neutralized, enabling them to clump together and form larger aggregates that can be more easily separated during subsequent treatment stages.

The importance of coagulation extends across a wide spectrum of industrial wastewater treatment methods. For example, in primary treatment, coagulation provides the first step in reducing turbidity and removing suspended solids. In more advanced systems, it supports secondary and tertiary treatment processes by improving the efficiency of biological and physical separation.This article explores how advanced coagulation techniques, supported by ETI’s custom chemical blending expertise, go beyond conventional practices to help industries manage increasingly difficult wastewater challenges while aligning with sustainability and compliance goals.

Fundamentals of Coagulation in Wastewater Treatment

Coagulation is one of the cornerstones of wastewater treatment because it directly addresses one of the most difficult challenges in water management: removing very fine particles that do not easily settle on their own. These particles, which can include clay, organic matter, and colloidal solids, remain suspended in water due to their electrical charges. Left untreated, suspended solids contribute to turbidity, reduce treatment efficiency, and carry with them pollutants such as heavy metals or organic compounds.

How Coagulation Methods Work

Coagulation methods introduce chemical agents that neutralize the charges on suspended particles, allowing them to destabilize and bond together. Once the repulsive forces are overcome, the particles aggregate into larger clusters, which can then be removed through sedimentation, flotation, or filtration. This step is essential for both primary and secondary treatment, improving clarity and reducing the pollutant load before further treatment stages.

Advanced Chemical Coagulation Techniques

Coagulation has long been recognized as one of the most effective ways to improve water clarity and reduce pollutant loads. However, as wastewater streams become more complex, industries are turning to advanced coagulation methods that extend beyond traditional practices. These updated approaches improve removal of heavy metals, neutralize toxic compounds, and integrate seamlessly with both physical and biological processes.

Traditional vs. Advanced Coagulation Methods

| Aspect | Traditional Methods | Advanced Methods |

|---|---|---|

| Chemicals Used | Simple salts like alum and ferric chloride | Polymer-enhanced coagulants, blended formulations |

| Target Pollutants | Suspended solids and turbidity | Heavy metals, toxic compounds, organic pollutants |

| Process Efficiency | Effective for basic clarity improvement | Higher removal rates, even with challenging wastewater streams |

| Integration | Standalone chemical treatment step | Linked with activated sludge process and advanced treatment technologies |

| Sludge Generation | Higher volumes of waste sludge | Reduced sludge, easier dewatering |

Chemical Precipitation and Heavy Metal Removal

One of the most important applications of advanced coagulation is chemical precipitation. This process involves converting dissolved contaminants into insoluble particles that can be separated from the wastewater. It is particularly effective for removing heavy metals such as lead, cadmium, and chromium, which pose serious risks to both human health and the environment.

Tackling Toxic Compounds and Complex Streams

Industrial wastewater often contains toxic compounds that cannot be addressed through conventional physical methods alone. Advanced coagulant blends are designed to neutralize these pollutants, making them less harmful and easier to remove during secondary or tertiary treatment stages. In systems with high concentrations of organic materials, polymeric coagulants can capture and stabilize fine particles that would otherwise bypass treatment.

Integration with Biological Processes

Another distinguishing feature of advanced coagulation methods is their compatibility with biological systems. In the activated sludge process, for instance, coagulation can be used as a pretreatment step to reduce the burden of suspended solids and toxic contaminants. By improving influent quality, the efficiency of biological degradation increases, reducing the likelihood of process upsets and helping facilities maintain compliance with discharge permits.

Advanced coagulation is not just about achieving clearer water; it represents a strategic approach to managing the growing complexity of industrial wastewater streams. Through carefully selected coagulant formulations and integrated treatment designs, facilities can meet stricter regulations, reduce sludge volumes, and lower overall operational costs.

Also read our blog: Temperature and Its Effects on Coagulation Process in Water Treatment

Hybrid and Innovative Coagulation Approaches

Industrial wastewater streams rarely contain a single type of contaminant. They often include suspended solids, organic pollutants, and dissolved metals, all of which require more than a one-step process. This has given rise to hybrid systems that integrate coagulation methods with other treatment technologies, ensuring a broader spectrum of pollutant removal and higher efficiency.

1. Coupling Coagulation with Filtration

The first step in many hybrid designs is coagulation, which destabilizes fine particles. These flocs are then captured through sand, membrane, or advanced filtration. This combination allows for tertiary treatment of wastewater, removing very fine particles and pathogens that escape earlier stages.

2. Linking Coagulation with Biological Treatment

When paired with biological systems, coagulation methods reduce toxic loads and improve the conditions for microbial degradation. This synergy enhances the performance of processes like activated sludge, reducing the risk of process failures and ensuring more stable effluent quality.

3. Advanced Coagulation with Oxidation Processes

In facilities handling complex chemical mixtures, coagulation is often combined with oxidation methods such as ozone or chlorine dioxide. The coagulation step removes solids and some organics, while oxidation breaks down residual organic pollutants or neutralizes pathogens. This layered approach represents a strong example of further treatment beyond conventional systems.

Innovative Solutions in Coagulation

Beyond hybrid systems, several innovative solutions are redefining what coagulation can achieve:

- Magnetic Coagulation: Magnetic particles are combined with coagulants, enabling rapid separation using magnetic fields. This reduces settling times and improves efficiency.

- Nanomaterial-Enhanced Coagulation: Engineered nanoparticles are used to destabilize contaminants more effectively, targeting very fine or stable particles.

- Electrocoagulation: Electric currents are applied to dissolve metal electrodes, releasing ions that act as coagulants. This method reduces chemical demand and produces smaller volumes of waste sludge.

- Green Coagulants: Natural polymers and plant-based materials are gaining attention as sustainable alternatives to traditional metal salts.

Hybrid and innovative coagulation methods are helping industries meet increasingly strict discharge standards while optimizing costs. By combining traditional strengths with new technologies, wastewater treatment operators can achieve cleaner effluent, reduced waste, and more resilient treatment performance.

Industry-Specific Applications

The versatility of advanced coagulation methods is best understood by looking at how they are applied across different industries. Each sector generates unique wastewater streams, requiring targeted treatment strategies that address specific pollutants while maintaining compliance with federal regulations.

Food Processing Facilities

Food production generates large volumes of wastewater containing fats, oils, grease, and organic byproducts. Coagulation plays a key role in stabilizing these streams before biological or physical treatment stages.

- Grease and fat removal: Specialized coagulants break down emulsified fats that would otherwise escape treatment.

- Organic load reduction: High concentrations of proteins, sugars, and other organic materials are destabilized, lowering biochemical oxygen demand (BOD).

- Solids capture: Suspended food particles are aggregated and removed, reducing strain on secondary systems.

- Improved sludge handling: Coagulation reduces excess solid waste volume, making disposal and recycling more manageable.

Pharmaceutical Manufacturing

Wastewater from pharmaceutical facilities is often complex, with high-strength chemical residues that can be toxic to the environment. Advanced coagulation offers one of the most reliable solutions for such streams.

- Organic pollutant removal: Coagulants capture dissolved organic chemicals and drug residues, preventing discharge into water bodies.

- Toxic compound neutralization: Blended formulations reduce the impact of reactive compounds on downstream treatment systems.

- Compliance assurance: Stringent federal regulations for pharmaceutical effluents demand precise treatment, which coagulation helps achieve.

- Integration with tertiary treatment: Coupling with advanced oxidation or membrane systems ensures removal of trace contaminants.

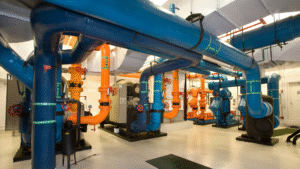

Industrial Plants and Facilities

Heavy industries, ranging from energy to petrochemicals, face some of the toughest challenges in wastewater treatment. Advanced coagulation is a cornerstone for managing these diverse streams.

- Cooling tower blowdown: Coagulation assists in removing scale-forming ions and corrosion byproducts, reducing the environmental risks of blowdown water.

- Gas extraction processes: Wastewater from extraction activities contains dispersed hydrocarbons and fine particulates, which coagulation helps to aggregate for easier separation.

- Metal and mineral industries: By precipitating and removing heavy metals, coagulants protect receiving waters and ensure compliance with discharge permits.

- Manufacturing processes: Across manufacturing facilities, wastewater often contains a mixture of oils, dyes, and suspended solids. Coagulation ensures consistency in treatment before biological polishing.

- Solid waste management: Coagulation reduces sludge volumes, improving efficiency in waste handling for large industrial plants and industrial facilities.

Advanced coagulation’s adaptability makes it an essential tool for industries as diverse as food processing, pharmaceuticals, and heavy manufacturing. By targeting specific pollutants in each sector, facilities not only safeguard water quality but also streamline operations and reduce long-term costs.

Managing Waste Streams and Sludge

While coagulation methods are highly effective in removing pollutants, they also produce byproducts that must be managed responsibly. The treatment of waste sludge and the handling of complex waste streams are critical components of industrial wastewater management. Without proper disposal and treatment strategies, these byproducts can offset the environmental benefits of wastewater treatment.

Step-by-Step Process of Sludge and Waste Stream Management

- Collection and Concentration

- During coagulation, pollutants and suspended solids aggregate into larger particles, forming sludge.

- This waste sludge is separated from the treated water using sedimentation or flotation units.

- Dewatering and Volume Reduction

- The sludge is thickened through centrifuges, belt presses, or filter presses to remove excess water.

- Reducing volume makes handling more cost-effective and decreases the burden of final disposal.

- Stabilization of Organic Waste

- Industrial wastewater often contains large amounts of organic waste and organic compounds.

- Conditioning treatments, such as lime addition or digestion, stabilize these materials to prevent odors and minimize environmental risks.

- Disposal or Beneficial Reuse

- Sludge can be incinerated, landfilled, or in some cases, repurposed for energy recovery or land application, depending on regulatory approvals.

- Facilities must comply with strict wastewater discharge standards when returning treated water to water bodies or publicly owned treatment works.

- Continuous Monitoring

- Because industries generate wastewater with varying characteristics, monitoring systems are essential to adjust coagulant dosing and sludge handling methods.

- Adaptive management ensures that facilities remain in compliance while effectively treating wastewater produced from diverse processes.

By following these steps, industries can transform coagulation byproducts from an operational challenge into a manageable component of the treatment cycle. Effective sludge management not only reduces environmental impact but also supports long-term sustainability goals.

ETI’s Expertise in Advanced Coagulation Solutions

For nearly four decades, ETI has specialized in custom-formulated chemical solutions that help industries achieve cleaner water, reduced costs, and long-term compliance. When it comes to advanced coagulation methods, ETI provides one of the most comprehensive portfolios in the market, combining traditional inorganic coagulants with next-generation organic and blended formulations.

Our coagulants are engineered to address the growing complexity of industrial wastewater treatment. Whether the challenge is suspended solids, heavy metals, or organic pollutants, ETI’s solutions are designed to improve clarification performance while minimizing sludge generation and optimizing chemical usage. By pairing advanced coagulants with downstream treatment technologies, industries can achieve higher efficiency, reduce operational costs, and ensure compliance with environmental standards.

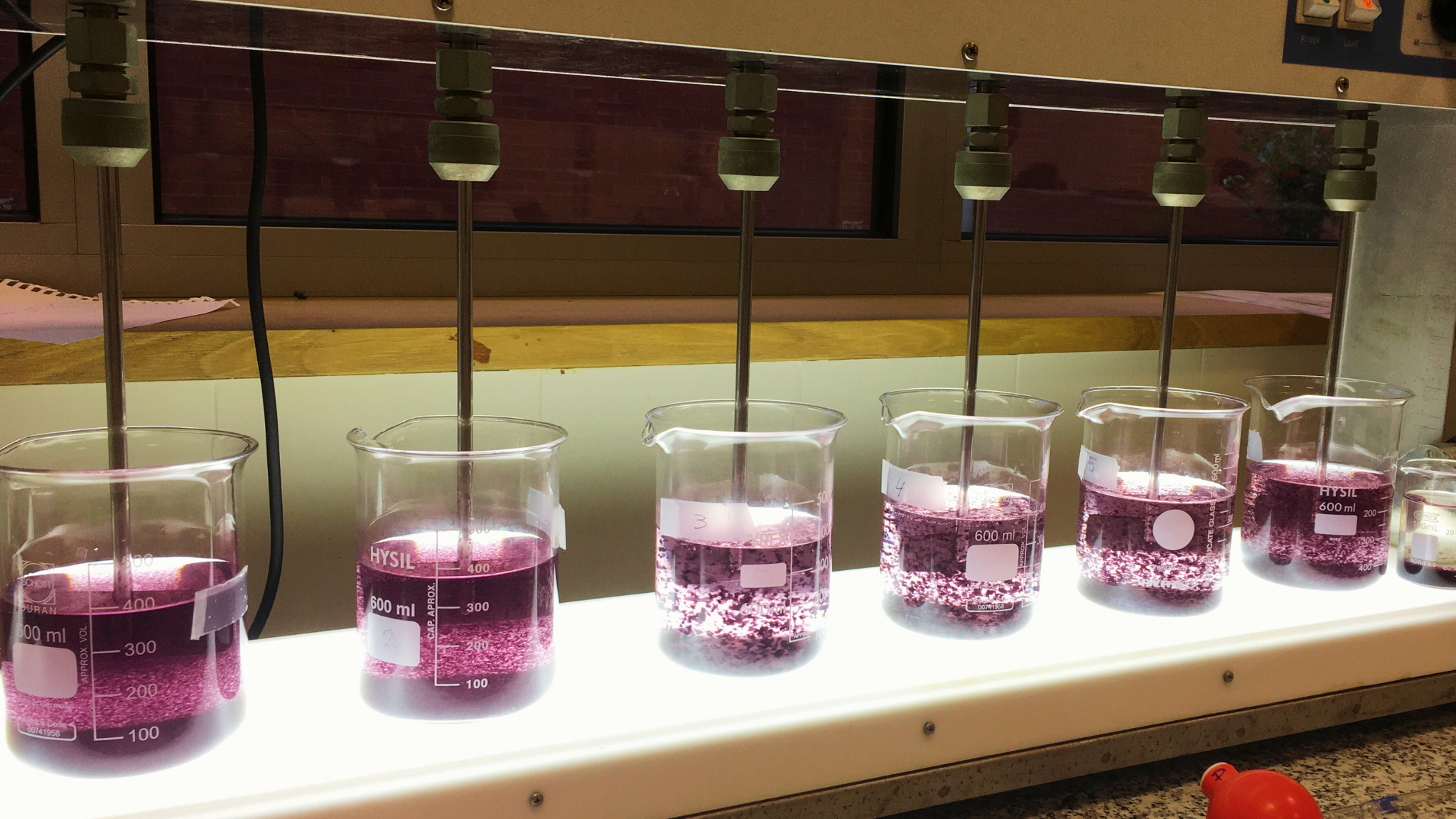

ETI supports a wide range of industrial processes including food and beverage, pharmaceuticals, petrochemicals, textiles, and municipal water treatment. With a hands-on approach that includes system assessment, bench testing, and continuous optimization, ETI ensures that clients receive more than just a product — they gain a long-term partner in water management.

Explore ETI’s Coagulant Solutions

- Advanced Coagulant Water Treatment Solutions – Superior clarification technologies engineered for industrial and municipal applications, delivering enhanced floc formation, broader pH performance windows, and reduced sludge production.

- Advanced Organic Coagulants for Superior Contaminant Removal – High-performance organic coagulants designed to reduce sludge volume, improve contaminant removal, and enhance environmental compatibility.

- Efficient and Reliable Inorganic Coagulation for Industrial Wastewater Treatment – Inorganic coagulants optimized for robust suspended solids removal and cost-effective treatment in high-volume wastewater streams.

By integrating ETI’s coagulant technologies into your water treatment strategy, you can ensure consistent system performance, meet stricter discharge requirements, and operate more sustainably.

Also explore our complete set of wastewater treatment products.

Driving Cleaner Water with Advanced Coagulation Methods

As industries continue to face mounting regulatory pressures and increasingly complex wastewater streams, advanced coagulation methods remain a cornerstone of reliable treatment performance. From removing suspended solids and heavy metals to stabilizing organic loads, coagulation enables facilities to manage industrial wastewater more effectively, safeguard water resources, and maintain compliance with environmental standards.

The innovations shaping coagulation today — hybrid treatment designs, organic and polymer-enhanced formulations, and sustainable green chemistries — make it possible for facilities to optimize efficiency while reducing costs. More importantly, advanced coagulation ensures that industries can move beyond compliance to achieve operational resilience and environmental stewardship.

Take the Next Step with ETI

At ETI, we understand that no two wastewater streams are alike. Our custom-blended coagulants are engineered to meet the exact needs of each client, ensuring optimal performance across industries as diverse as food processing, pharmaceuticals, mining, and petrochemicals. Backed by decades of expertise in chemical blending and hands-on technical support, ETI helps partners meet their toughest water treatment challenges head-on.

If your facility is looking to improve water clarity, reduce sludge volumes, or comply with stricter discharge regulations, ETI has the solutions you need. Contact us today to discover how our advanced coagulant technologies can transform your treatment performance.

Frequently Asked Questions (FAQs)

What does the coagulation process involve in wastewater treatment?

The process involves adding chemical agents that neutralize the charges of fine particles in wastewater. Once destabilized, these particles aggregate into larger flocs that can be removed through sedimentation, filtration, or flotation, improving overall system clarity.

What is the role of an aeration tank after coagulation?

An aeration tank is part of the activated sludge process, following coagulation and sedimentation. It introduces oxygen to support microbial degradation of organic pollutants, reducing the load of contaminants before secondary or tertiary treatment.

How does coagulation address unwanted metals at high concentrations?

Many industrial facilities generate wastewater containing unwanted metals at high concentrations. Coagulation precipitates these metals into insoluble forms that can be captured in sludge, ensuring compliance with discharge standards and protecting receiving waters.

How does coagulation help with wastewater sent to publicly owned treatment works (POTWs)?

Pretreating effluent before it reaches publicly owned treatment works reduces the burden on municipal systems. Coagulation lowers levels of suspended solids, oils, and heavy metals, improving compatibility with downstream treatment processes.

What is the role of the activated sludge process alongside coagulation?

The activated sludge process is a biological treatment stage that uses microorganisms to break down dissolved and organic pollutants. When paired with coagulation, the overall efficiency improves significantly. Coagulation reduces suspended solids and toxic loads before wastewater enters the aeration tank, creating a more stable environment for microbial activity. ETI’s coagulant formulations are often used as a pretreatment step to optimize activated sludge performance and prevent process disruptions.

Can coagulation methods improve cooling water treatment?

Yes. In industrial facilities, coagulation enhances cooling water quality by reducing particulates and organic matter that can cause scaling, fouling, or microbial growth. This improves heat transfer efficiency and extends equipment lifespan.