When facility managers and water treatment operators ask, “what is grease trap?” the answer often begins in the kitchen but ends at the treatment plant. A grease trap, sometimes called a grease interceptor, is a crucial plumbing device that prevents fats, oils, and grease (FOG) from entering the sanitary sewer system. Though these systems are most familiar in food service establishments and commercial kitchens, the principles behind them extend directly into industrial water treatment—where similar chemistry governs the management of FOG and other suspended solids.

Understanding grease traps is not only important for restaurants trying to meet local codes. For engineers and operators overseeing industrial wastewater flows, it provides valuable insight into how contaminants behave when wastewater enters a collection system. Every grease trap demonstrates how separation, flow control, and regular maintenance protect downstream systems from clogs, foul odors, and sanitary sewer overflows.

At its core, a grease trap is an early lesson in fog management. It shows how chemical and physical processes can separate grease from water before it reaches the city sewer system or a septic tank. In industrial facilities, this same science applies on a larger scale through clarifiers, separators, and treatment basins—all designed to maintain clean effluent and compliant discharge. This article explores how grease traps work, their types, cleaning methods, and what they teach us about maintaining efficient wastewater systems. By the end, you will understand why the answer to “what is grease trap” also answers a bigger question: how does chemistry safeguard the entire water treatment process?

The Basics: What Is Grease Trap?

To understand the fundamentals of wastewater pre-treatment, it helps to begin with the basics: what is grease trap and why does it matter? A grease trap, also known as a grease interceptor, is a containment device installed in a plumbing system to capture fats, oils, and grease (FOG) before they enter the main sewer lines. These contaminants, when mixed with food solids and other solid debris, can solidify and create grease blockages that restrict flow and cause backups in both commercial and industrial settings.

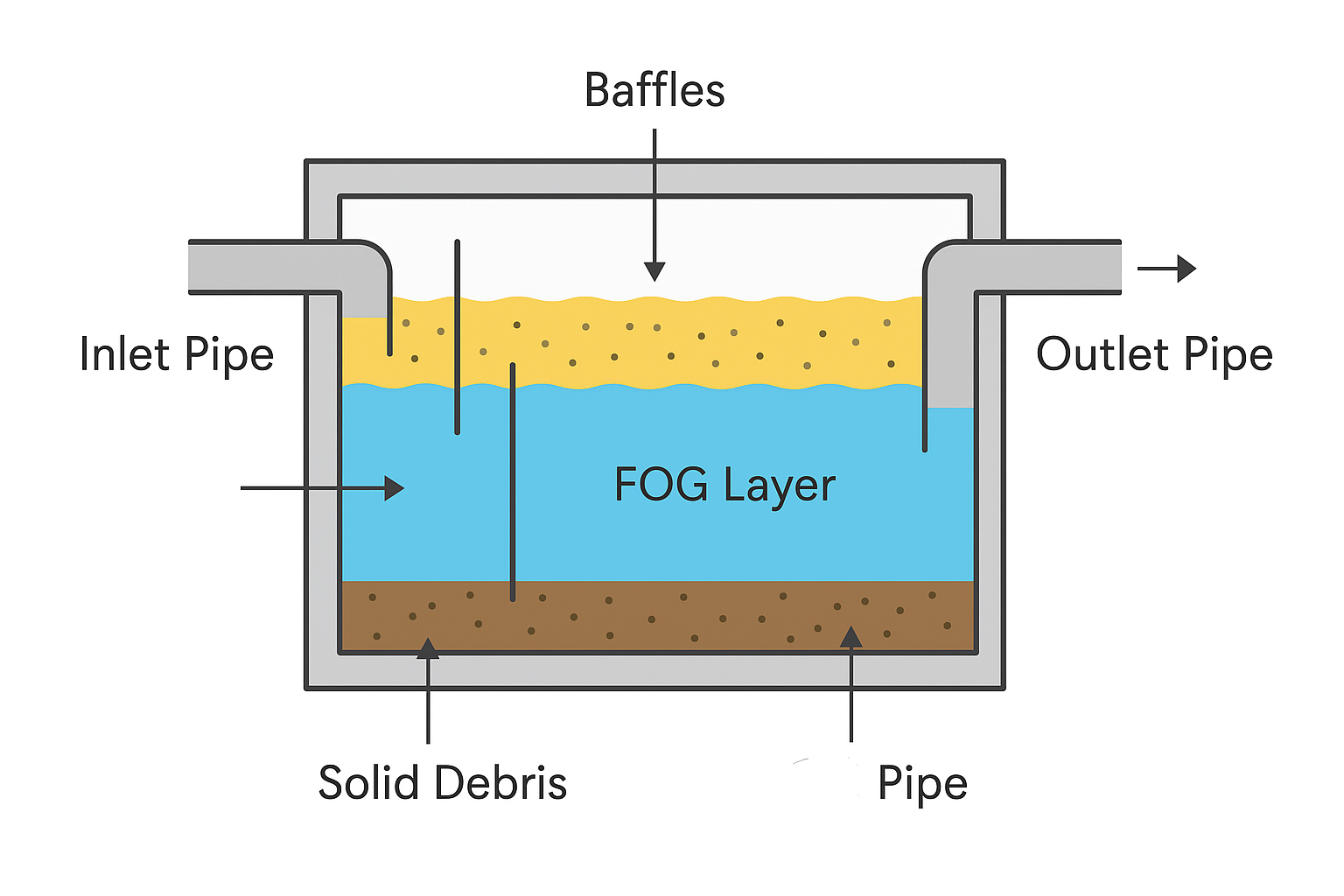

A grease trap works by slowing down wastewater flows as they enter through an inlet pipe. Inside the trap, metal barriers and baffles guide the liquid, allowing fats, oils, and grease to rise to the surface while solids sink to the bottom. Cleaner water exits through an outlet pipe or outlet baffle, flowing onward to the sanitary sewer system or septic tank. In essence, grease traps function like miniature sedimentation tanks, designed specifically to separate grease from water.

There are several types of grease traps used in various food service establishments and industrial applications:

- Manual Grease Traps (Passive Systems): Often called passive grease traps, these units rely on gravity separation. They are common in smaller kitchens and are typically cleaned manually on a scheduled basis.

- Automatic Grease Traps: Also known as automatic grease removal units, these systems include mechanical components that pump or skim collected grease into a separate container for disposal. They suit high flow applications where grease generation is frequent.

- Hydromechanical Grease Interceptors: A more advanced design that enhances separation using flow control devices, baffles, and increased flow rate efficiency. These are common in larger units serving multiple floor drains, sinks, and mop sinks.

Regardless of type, all grease traps serve the same purpose: to prevent fats, oils, and grease from reaching the city sewer system, where they can cool, solidify, and contribute to sanitary sewer overflows. Understanding this foundational system offers valuable insight into the chemistry of fog management and wastewater treatment efficiency.

Also read: Grease Trap Chemicals: Pros, Cons, and Blending Solutions Every Treatment Pro Should Know

How Grease Traps Work (Step-by-Step)

To fully appreciate how grease traps work, it helps to visualize the path wastewater takes through the system. Whether in a commercial kitchen, a food service facility, or an industrial plant, the process begins when wastewater enters the trap through an inlet pipe. This stream typically contains fats, oils, and grease, along with food solids, vegetable oils, animal fats, and other solids from sinks, mop sinks, or floor drains.

1. Flow Control and Separation

Inside the trap, the flow rate is intentionally slowed to allow the contents to separate naturally. The baffles and metal barriers create a controlled environment where the heavier solids and food debris settle to the bottom, while lighter materials such as fats oils and grease (FOG) float to the surface. This separation is the key principle behind all traditional passive systems and hydromechanical grease interceptors.

2. Containment and Cooling

As the mixture cools, fats oils and grease begin to solidify, forming a distinct top layer. The space between this upper grease layer and the bottom layer of solid debris holds relatively clear water. The system follows what is often called the “one fourths rule”, meaning the trap should be cleaned when FOG and solids together occupy one-fourth of the tank’s volume. Ignoring this rule can lead to back up, reduced flow, and unpleasant foul odors.

3. Effluent Discharge

After separation, the cleaner water flows out through the outlet baffle and outlet pipe, continuing on to the sanitary sewer or septic tank. This step prevents untreated wastewater from reaching the city sewer system, where FOG accumulation can create massive grease blockages and even contribute to sanitary sewer overflows.

4. Regular Cleaning and Maintenance

Because many grease traps collect both grease and solids continuously, regular cleaning on a scheduled basis is essential. This ensures that the trap continues to perform effectively and prevents excessive accumulation that might reach the sewer system or affect nearby drainage systems.

The Chemistry Behind FOG Management

At the heart of every grease trap lies a practical demonstration of chemistry in motion. To understand what is grease trap from a scientific perspective, we must look beyond plumbing components and focus on how fats, oils, and grease (FOG) interact with water. The reason grease traps work so effectively is due to a simple chemical principle—immiscibility—which means that substances such as oil, animal fats, and vegetable oils do not mix with water. Instead, they separate based on density, allowing the trap to isolate them before they cause issues in the sewer system.

In a functioning grease trap or grease interceptor, fog management depends on temperature, flow rate, and chemistry. Hot water initially keeps oils and grease fog in suspension, but as the liquid cools, these compounds congeal and float upward. The trap’s design and baffles create the right conditions for this natural phase separation to occur. However, when water temperature is too high or the system receives chemical discharge from cleaning agents, emulsification can occur, causing FOG to remain mixed with wastewater and pass through the outlet pipe into the sanitary sewer system.

Grease Trap Types and Applications

Although the concept of separating fats, oils, and grease from water is simple, the design and function of grease traps vary significantly depending on size, flow requirements, and the nature of the facility. Understanding the main categories helps engineers, maintenance teams, and facility operators choose the most effective system for their operations and prevent grease blockages within the plumbing system or city sewer system.

Passive Grease Traps (Traditional Systems)

Passive grease traps, also called manual grease traps, are the most common type used in food service establishments and smaller facilities. These traditional passive systems rely solely on gravity to separate grease from wastewater. They contain internal baffles that slow the flow rate, allowing fats oils and grease to rise and solid debris to settle. Passive systems are affordable and straightforward but require frequent cleaning to prevent buildup and odors.

Automatic Grease Removal Units

Automatic grease traps, or automatic grease removal units (AGRUs), integrate mechanical skimmers or pumps that transfer collected grease into a separate container for disposal. These systems are ideal for high flow applications, such as large commercial kitchens or food production facilities, where grease accumulates quickly. Their design reduces manual maintenance, supports consistent performance, and minimizes downtime.

Hydromechanical Grease Interceptors

Hydromechanical grease interceptors combine gravity separation with engineered flow controls to enhance FOG removal. They handle larger volumes of wastewater flows and are commonly installed in industrial settings where the inlet pipe connects multiple sinks, mop sinks, or floor drains. These larger units maintain efficiency and reduce the likelihood of sanitary sewer overflows.

Selecting the right system is crucial for maintaining compliance, ensuring regular cleaning, and protecting downstream components. Each type plays a key role in a facility’s overall grease management and wastewater pre-treatment strategy.

Maintenance and Cleaning: Keeping Systems Functional

Every facility operator who understands what is grease trap also knows that its performance depends on regular cleaning and maintenance. Even the most advanced grease interceptor or automatic grease trap will fail to protect the sanitary sewer system if it is not properly cleaned on a scheduled basis. Over time, fats, oils, and grease (FOG) solidify and mix with food solids, forming dense layers that reduce flow and eventually lead to grease blockages, foul odors, and even back up into sinks and drains.

The Importance of Routine Maintenance

Routine grease trap cleaning removes accumulated grease, sludge, and solid debris from the system. This prevents overflow and ensures that the outlet pipe and inlet pipe remain unobstructed. Most local governments enforce cleaning regulations to prevent untreated discharge into the sewer or sanitary sewer system, which can lead to sanitary sewer overflows and environmental contamination. The frequency of cleaning depends on the flow rate, grease volume, and size of the trap, but as a rule of thumb, the system should be cleaned when one-fourth of its volume is filled with FOG and solids—the one fourths rule.

Cleaning Methods

- Manual Cleaning: Common for manual grease traps or passive systems, this involves physically removing grease and sludge, followed by rinsing the trap with warm water. The collected material is then disposed of through approved environmental services.

- Automated or Pump-Based Cleaning: Automatic grease removal units often include a pump or skimmer that transfers grease to a separate container. While these systems reduce labor, they still require inspection to ensure proper operation.

- Professional Maintenance: Partnering with licensed environmental services or wastewater professionals ensures the trap is cleaned according to local codes and waste is managed responsibly.

Why Neglect Causes Problems

Neglecting cleaning schedules allows fats oils and grease to harden, clogging the drainage system and sewer lines. These conditions are a leading cause of sanitary sewer overflows and corrosion in municipal systems. In industrial facilities, ignoring maintenance can disrupt the entire wastewater flow, forcing costly downtime and emergency repairs.

Consistent cleaning, paired with monitoring and documentation, ensures that the grease trap continues to protect the plumbing system, sewer system, and the environment. Maintenance is not simply a regulatory checkbox—it’s an essential step in responsible grease management.

ETI’s Expertise in Grease and Wastewater Chemistry

At ETI, understanding grease trap goes beyond basic system function—it reflects decades of experience in chemical blending and wastewater treatment innovation. Since 1986, ETI has specialized in developing advanced chemical solutions that help facilities manage fats, oils, and grease (FOG) efficiently while maintaining environmental compliance and reducing maintenance costs.

Grease traps and grease interceptors are only as effective as the chemistry behind them. ETI’s biological grease trap treatments use natural bacteria and enzymes to digest FOG at the molecular level, improving flow and minimizing grease blockages. For facilities requiring faster action, our FOG control and emulsifier formulations prevent grease from solidifying in pipes and drainage systems, maintaining smooth operation across commercial kitchens and industrial water systems. To complement these products, ETI offers odor control and organic waste treatments that neutralize foul odors, target sulfur compounds, and enhance hygiene in high-grease environments. For critical cleanouts or overloaded traps, ETI’s heavy-duty grease trap cleaners remove hardened buildup to restore system efficiency.

ETI’s approach is rooted in chemistry, service, and partnership. We assess your facility’s needs, design customized formulations, and provide hands-on technical support and preventive maintenance guidance. From restaurants to municipal wastewater treatment plants, our products and expertise help clients prevent grease buildup, protect the sanitary sewer system, and sustain efficient wastewater flows. Contact ETI to learn more about optimizing your grease trap maintenance program or developing a tailored solution for your operation.

Frequently Asked Questions (FAQ)

What is the difference between a grease trap and a grease interceptor?

A grease trap is typically a smaller, internal unit that captures fats, oils, and grease (FOG) from sinks and floor drains, while a grease interceptor or hydromechanical grease interceptor is a larger, external unit designed for high flow applications. Both systems help prevent grease from entering the sanitary sewer system and causing grease blockages or sanitary sewer overflows.

How often should grease traps be cleaned?

Many grease traps should be properly cleaned on a scheduled basis, usually when one-fourth of the tank’s volume contains grease and solid debris. This “one fourths rule” helps maintain optimal flow rate and prevents system backup.

What causes foul odors in grease traps?

Foul odors usually result from decomposing animal fats, vegetable oils, and food solids trapped inside the system. Regular grease trap cleaning and ETI’s odor control treatments eliminate these smells and improve hygiene.

Do automatic grease traps reduce manual labor?

Yes. Automatic grease removal units include mechanical components that pump grease into a separate container for disposal. They minimize manual effort but still require inspection and maintenance to ensure reliable performance.

Does ETI provide a heavy-duty grease trap cleaner?

Yes. ETI’s heavy-duty grease trap cleaner rapidly removes hardened grease and buildup in neglected systems. It is ideal for commercial kitchens, food service establishments, and other solids-heavy environments requiring deep cleaning.

How do grease traps connect to other plumbing fixtures?

Most traps link directly to mop sinks, drainage systems, or floor drains via an inlet pipe and outlet pipe. These connections help collecting solid debris and separate grease before the wastewater exits to the sewer lines beneath manhole covers.