In every steam and boiler system, condensate is one of the most valuable resources a facility can capture and reuse. When steam condenses after transferring its heat, the resulting water is typically pure and hot, making it ideal for returning to the boiler cycle. Yet without proper condensate treatment, this resource can quickly become a source of corrosion, maintenance problems, and costly inefficiencies.

The main culprits are oxygen and carbon dioxide. Even in small amounts, these gases interact with metal piping and equipment in ways that steadily weaken the system. Oxygen encourages localized pitting, while carbon dioxide dissolves into the water and forms carbonic acid that drives down pH. Together, they attack steel, copper, and other metals, causing leaks, deposits, and increased repair needs.

Understanding how condensate corrosion occurs and how to stop it is essential for any facility that depends on reliable steam production. This article explores the chemistry behind oxygen and carbon dioxide corrosion, the role of condensate return in protecting boiler systems, and why blended amines are considered the most effective strategy for long-term corrosion control. By examining both the risks of untreated condensate and the benefits of tailored solutions, we can see why condensate treatment is not simply a best practice but a critical step in efficient, sustainable boiler operation.

What is Condensate and Why It Matters

Condensate is the water formed when steam condenses after transferring its heat to a process or piece of equipment. Unlike raw make up water, which contains minerals and impurities, condensate is essentially high-purity distilled water. This makes it an incredibly valuable resource in industrial operations. Facilities that recover and reuse condensate reduce the need for chemical pretreatment, lower fuel consumption, and improve overall system efficiency.

One of the most important aspects of condensate management is returning condensate to the boiler. Each gallon of water returned is one less gallon of makeup that must be treated, heated, and fed into the system. This recycling translates directly into reduced operating expenses, decreased chemical demand, and fewer contaminants introduced into the cycle. For plants looking to cut maintenance costs while maintaining reliability, maximizing condensate return is one of the most cost effective strategies available.

The benefits extend beyond economics. Because condensate is already hot, its reuse reduces the amount of energy needed to raise water to steaming temperature. It also minimizes the volume of blowdown required to control solids in the boiler, which further conserves water and chemicals. From a sustainability standpoint, efficient condensate recovery supports corporate environmental goals while protecting critical condensate systems from excessive wear.

The Chemistry of Corrosion in Condensate Systems

Corrosion in condensate lines is primarily driven by two gases: oxygen and carbon dioxide. Even in trace amounts, these gases interact with metals in the system, setting off chemical reactions that steadily degrade piping, traps, and other components.

Oxygen and Pitting Corrosion

Oxygen is one of the most aggressive corrosive agents in condensate systems. When dissolved in hot water, oxygen attacks steel and other metals, creating small but deep pits on the surface of the piping. These pits weaken the integrity of the system and can quickly lead to leaks. Because oxygen is introduced through boiler feedwater or air leaks, it must be removed or neutralized before causing serious damage. This is where an oxygen scavenger plays a role, binding with dissolved oxygen to minimize the risk of localized attack.

Carbon Dioxide and Carbonic Acid Formation

The second major culprit is carbon dioxide content carried over in the steam. As steam cools and condenses, carbon dioxide dissolves into the water, forming carbonic acid. This weak acid significantly lowers the pH of condensate, sometimes to levels below 5.5, which accelerates general metal loss. Both iron and copper piping are vulnerable, and the resulting oxides and corrosion products eventually cycle back to the boiler, reducing efficiency and fouling equipment.

The Role of Temperature and Pressure

Condensate temperature and system pressure also play a role in how gases behave. Higher pressures increase the release of carbon dioxide when steam condenses, while lower temperatures allow oxygen to dissolve more readily into the water. This interplay means that even small shifts in operating conditions can influence corrosion rates.

Corrosion is not a single reaction but an ongoing process that depends on chemistry, gas concentration, and system design. Understanding these interactions is the first step toward effective corrosion control and reliable protection of condensate infrastructure.

Also read: Boiler Water Treatment Guide: From pH Control to Oxygen Scavengers

The Impact of Untreated Condensate on Boiler Systems

When condensate is left untreated, corrosion products and gas-related reactions create a ripple effect that harms multiple parts of the steam cycle. The consequences show up not only in the piping but also inside the boiler and connected equipment.

Key Impacts of Untreated Condensate

- Clogged steam traps

- Corrosion debris accumulates in traps, restricting proper drainage.

- Malfunctioning steam traps increase energy loss and compromise safe operation.

- Fouling of boiler feedwater lines and tubes

- Corroded metal particles, particularly iron oxides, are carried back into the boiler feedwater system.

- Deposits reduce heat transfer and increase fuel usage.

- Reduced efficiency and higher fuel consumption

- Deposits on tube surfaces act as insulation, forcing the heating process to work harder.

- More fuel must be burned to maintain the same steam output, decreasing overall efficiency.

- Shortened equipment lifespan

- Continuous operation under corrosive conditions erodes piping and boiler components.

- Leads to costly premature replacement of lines, valves, and traps.

- Increased maintenance costs

- Facilities face recurring expenses to clean, repair, or replace affected piping and equipment.

- Downtime during repairs impacts the entire site or plant process.

Example from Industrial Practice

In many plants, untreated condensate has resulted in heavy iron deposition inside boilers, reducing energy transfer and threatening safe operation. Once this type of scaling occurs, cleaning and repair become time-consuming, labor-intensive, and expensive.

Methods of Corrosion Control in Condensate Systems

Effective corrosion control in condensate lines requires a mix of mechanical, pretreatment, and chemical strategies. Each method addresses a different aspect of the problem, from limiting gas entry to neutralizing corrosive reactions after steam condenses.

Pretreatment Approaches

- Reverse osmosis (RO)

- Removes alkalinity and dissolved solids from make up water before it enters the system.

- Reduces carbon dioxide content generated inside the boiler.

- Dealkalization

- Specifically lowers carbonate and bicarbonate levels in feedwater.

- Prevents formation of carbonic acid in condensate.

- Filtration and polishing

- Removes fine contaminants that can foul piping.

- Improves long-term system cleanliness and reliability.

Mechanical Approaches

- Proper drains and blowdown systems

- Ensure that accumulated solids and air pockets are released safely.

- Prevent stagnant water that accelerates corrosion.

- Well-installed equipment

- Correctly installed traps, valves, and vents help maintain stable pressure and temperature.

- Reliable design reduces unplanned failures.

- Clean design and maintenance

- Regular inspection and flushing keep lines free of deposits.

- Lower risk of scaling and corrosion product buildup.

Chemical Approaches

- Oxygen scavengers

- Neutralize dissolved oxygen in boiler feedwater and condensate.

- Common agents include sodium sulfite, DEHA, and other reducing agents.

- Neutralizing amines

- Raise pH and counteract acidic conditions caused by dissolved CO₂.

- Applied to provide ongoing protection in return lines.

- Filming amines

- Create a thin hydrophobic layer on metal surfaces.Limit direct contact between water, oxygen, and carbonic acid.

Neutralizing and Filming Amines: Effective Protection

Among the most proven strategies for condensate treatment is the use of amines. These chemicals are specifically designed to provide effective protection against the corrosive reactions caused by dissolved gases. While amines can be applied individually, blended formulations often deliver more reliable and comprehensive results.

Neutralizing Amines

Neutralizing amines are alkaline compounds that dissolve into the steam and travel with it through the system. When the steam cools and condenses, these amines react with dissolved carbon dioxide to form salts, thereby raising the pH of the condensate. A higher pH reduces the acidity of the water and protects both steel and copper lines from general corrosion.

What makes neutralizing amines so versatile is their ability to be classified by range:

- Short-range amines protect near the boiler where condensate first forms.

- Medium-range amines provide protection in moderate-length piping.

- Long-range amines extend coverage to remote lines and equipment.

By combining amines with different ranges, operators can maintain consistent concentration and effective protection throughout the plant.

Filming Amines

Filming amines take a different approach. Instead of neutralizing acidity, they adsorb onto metal surfaces and create a thin hydrophobic barrier. This protective film prevents corrosive agents, such as carbonic acid and oxygen, from making contact with the metal itself. Although filming amines may require careful monitoring during application, their ability to provide long-term protection makes them highly valuable in aggressive environments.

The Value of Blending

In practice, the best results often come from using neutralizing and filming amines in conjunction. Neutralizers adjust the chemistry of the water, while filming agents provide a physical shield. Together, they deliver a level of reliability that single products cannot achieve on their own. For example, a sample program might include a neutralizing blend to raise pH and a filming amine to reinforce surfaces most exposed to acidic attack.

The note for operators is clear: amine selection and blending should be based on the specific conditions of the condensate system, including pipe length, temperature, and CO₂ load. When properly managed, amines offer cost-effective and dependable corrosion control.

The Role of Blended Amines in Modern Condensate Treatment

Industrial facilities no longer rely on single-component chemicals when it comes to condensate treatment. The complexity of today’s boiler systems, coupled with rising energy costs and environmental expectations, requires solutions that are adaptable, reliable, and proven in diverse operating conditions. This is where blended amines provide significant advantages.

Why Blended Formulations Work Better

Blended amines combine short-, medium-, and long-range neutralizers to provide uniform protection across both near and distant sections of piping. By tailoring the mix, operators can account for system length, pressure, and variations in condensate temperature. This ensures that corrosive carbon dioxide is neutralized consistently, even in remote return lines. When paired with filming amines, the blend provides both chemical neutralization and a physical barrier on metal surfaces.

Reliability Across Industries

For customers in Pennsylvania, Ohio, and other regions of the USA, blended amines deliver a balance of flexibility and reliability. Whether the facility is a food processor, a hospital, or a manufacturer, the ability to design a treatment program that addresses site-specific challenges is what makes blended chemistry so valuable. Operators can maintain a higher degree of system reliability, reduce downtime, and extend the life of equipment.

Cost and Maintenance Considerations

Blended amines also prove to be a cost effective approach. They reduce maintenance costs by minimizing corrosion-related failures, lowering the amount of make up water required, and keeping condensate lines cleaner. For plants facing tight budgets, avoiding unplanned shutdowns is often the most important factor in maintaining profitability.

A Matter of Long-Term Value

When evaluating treatment programs, facilities should take into account not just the immediate results but also the long-term value. Blended amines reduce the matter of risk by offering dependable protection against both oxygen and carbon dioxide corrosion. For organizations that see steam as a mission-critical utility, investing in blends is a way to ensure stable operation and measurable returns over time.

How ETI Supports Boiler Reliability Through Chemistry

At ETI Water, we understand that condensate treatment is not a stand-alone service but part of a broader strategy to protect boilers, piping, and steam distribution networks. Our role as a blending partner is to provide distributors and water treatment professionals with the chemical tools they need to keep systems running clean, efficient, and corrosion-free.

Oxygen Scavenger for Boilers

Because oxygen is one of the leading drivers of corrosion in condensate systems, effective removal is essential. ETI provides advanced Oxygen Scavenger for Boilers designed to eliminate dissolved oxygen from boiler feedwater, preventing pitting, scaling, and premature metal failure. These solutions are available in sulfite-based, DEHA, and erythorbate-based formulations, offering flexibility for different pressure and temperature conditions.

Rust Treatment for Boilers

Once corrosion begins, rust deposits can spread rapidly across equipment surfaces and inside boiler tubes. ETI’s Rust Treatment for Boilers uses advanced chemistry to dissolve existing rust while forming protective conditions that slow further oxidation. This treatment reduces maintenance costs, enhances efficiency, and extends boiler life across industries from power generation to food processing.

Custom-Blended Boiler Treatment Chemicals

No two facilities are alike. That is why ETI specializes in Custom-Blended Boiler Treatment Chemicals tailored to unique feedwater conditions, metallurgy, and operational parameters. Our blends include neutralizing and filming amines, corrosion inhibitors, and scale control additives engineered to work in synergy. By equipping distributors with flexible, cost effective solutions, ETI ensures that each site has reliable protection against oxygen, CO₂, and other contaminants.

Training and Support

Beyond products, ETI reinforces its position as a knowledge leader through training. Our ETI Bootcamp and 13-week CWT certification program prepare professionals to recognize condensate corrosion risks, evaluate treatment performance, and implement programs with confidence.

For distributors and operators in Pennsylvania, Ohio, and across the USA, ETI delivers not just chemistry but partnership — ensuring that systems are maintained, reliable, and ready for long-term operation.

Conclusion

Condensate may look like nothing more than water returning to the boiler, but its chemistry tells a much larger story. When steam condenses, it carries with it dissolved gases that, if left untreated, drive corrosion and shorten the lifespan of critical assets. Oxygen causes localized pitting, while carbon dioxide reduces condensate pH, creating conditions for widespread metal loss. Over time, the result is reduced efficiency, higher maintenance costs, and compromised reliability across the entire steam cycle.

That is why condensate treatment strategies built on blended amines and oxygen scavengers remain so important. By neutralizing acidity, forming protective films, and adapting to the specific conditions of each system, these treatments deliver long-term protection that single chemicals cannot match. For industrial facilities across Pennsylvania, Ohio, and beyond, investing in reliable treatment programs is not just about preserving equipment. It is about maintaining safe, cost-effective operation and protecting the value of every drop of water that moves through the boiler cycle.

As this article has shown, understanding the chemistry of corrosion is only the first step. Applying that knowledge with the right chemical blends ensures that condensate systems remain clean, efficient, and sustainable — a goal that benefits both the facility and the broader environment.

Ready to strengthen your boiler protection program? Contact ETI today to explore custom oxygen scavengers, rust treatments, and blended boiler chemical solutions tailored to your facility’s needs.

Frequently Asked Questions (FAQs)

What happens when condensate is lost instead of returned?

When condensate is discharged to drain or otherwise lost, the facility must replace it with fresh make up water. This increases chemical demand, raises fuel costs, and forces operators to handle more water than necessary. Returning condensate wherever possible is one of the most effective ways to reduce overall treatment expenses.

How does corrosion form inside condensate systems?

Corrosion is the result of chemical formation triggered by dissolved gases. When steam cools, carbon dioxide dissolves into the water and reacts to form carbonic acid. At the same time, oxygen can create localized pitting. Together, these reactions generate iron oxides and other products that damage piping and boiler components.

What can be done to remove or reduce corrosion products?

Facilities often install filtration systems and chemical programs to remove suspended solids and oxides from return lines. Blended amines and oxygen scavenger programs are designed to keep corrosive reactions in check, which significantly reduces the amount of corrosion debris that travels back to the boiler.

Why is clean condensate considered so valuable?

Condensate is essentially clean, high-purity water already at elevated temperature. Reusing it reduces energy demand for heating, lowers the chemical load needed for pretreatment, and improves boiler performance. Its purity also makes it one of the most effective resources in any steam-driven operation.

Does condensate treatment vary across different countries?

Yes. While the core chemistry of amine treatment and oxygen scavenging is similar worldwide, operating practices differ between countries depending on regulations, water quality, and industry standards. In the USA, for example, many facilities rely on blended amines to ensure reliable performance at every point in the return system.

What role does system pressure play in condensate treatment?

Pressure affects the amount of gas released when steam condenses. At low pressure, oxygen dissolves more easily in water, while higher pressures promote greater release of carbon dioxide. Both conditions need to be addressed with chemical treatment to protect equipment.

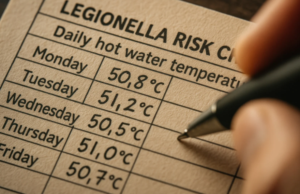

Are there guidelines or tables that operators can use to plan treatment?

Yes. Many treatment programs provide reference tables showing how CO₂ levels affect condensate pH and corrosion rates. These resources help operators identify the correct dosage and blend of neutralizing and filming amines to achieve optimal protection.