In both industrial and environmental water treatment, the use of a chemical dispersant plays a critical role in managing contaminants like oil, grease, or accumulated deposits. These substances often resist separation by conventional filtration or skimming, particularly when they form films or slicks on the water surface. Dispersants are specialized chemicals designed to break these hydrophobic substances into smaller droplets, allowing them to mix into the water column and be further processed, degraded, or removed.

Dispersant use is especially vital in response scenarios, such as oil spills in marine environments or grease accumulation in industrial effluent systems. In either case, the effectiveness of dispersants directly affects the ability of operators to control contamination, limit damage, and restore normal water conditions. However, despite their broad utility, these agents are not without challenges.

Improper selection, storage, application technique, or site conditions can all lead to problems during use. This article explores how chemical dispersants work, what can go wrong, and how to troubleshoot and resolve those issues to ensure safe, compliant, and cost-effective operation.

How Chemical Dispersants Work

To understand how to troubleshoot dispersant issues, it’s essential to know how chemical dispersants function in the first place. These compounds are formulated to disperse hydrophobic substances, such as oils or greases, into the water column by breaking them into smaller droplets. This increases the surface area available for microbial degradation or chemical oxidation, helping reduce long-term accumulation and environmental impact.

Dispersants typically contain surfactants, solvents, or other active chemicals that reduce surface tension at the boundary between the oil and water. When applied correctly, they aid in emulsifying thick substances, which helps prevent the formation of floating slicks or immobile surface deposits.

In industrial settings, effective dispersants are often used to manage unwanted buildup in wastewater, discharge systems, and treatment equipment. In environmental contexts, such as marine spill responses, they are applied to floating oil to mitigate surface contamination and help natural processes complete the breakdown.

Not all dispersants are equally effective in every situation. The choice of formulation depends on the type of contaminant, water temperature, salinity, mixing energy, and site-specific discharge requirements. A well-chosen dispersant can significantly aid treatment efficiency, but incorrect pairing or poor application can lead to diminished performance or unforeseen side effects.

Common Problems When Using Chemical Dispersants

Despite their advantages, chemical dispersants are not always a plug-and-play solution. Numerous variables can hinder their effectiveness or even cause operational setbacks. Understanding these common problems is the first step toward optimizing performance and ensuring safe, compliant treatment.

1. Temperature Sensitivity

Most dispersant formulations are engineered for specific temperature ranges. If the water is too cold, viscosity increases and the dispersant may not break down the target substances effectively. Conversely, excessive heat can degrade the product in storage, reducing its ability to function during application.

2. Incorrect Dispersant Selection

No single formulation is universally effective. Using a product that isn’t designed for your specific site conditions or contaminant profile can result in poor dispersant use outcomes. For instance, a dispersant meant for light hydrocarbons may underperform on heavier oil residues or thick greases.

3. Over-Application or Under-Dosing

Improper dosing can severely affect efficiency. Too much dispersant may create unwanted emulsions or toxic byproducts, increasing risks to aquatic organisms and human health. Too little dispersant may not achieve the necessary contact to disperse the oil phase, allowing accumulation or surface slicks to persist.

4. Degradation in Storage

Over time, dispersants may become less effective if exposed to sunlight, oxygen, or fluctuating temperatures. Old stock that hasn’t been tested regularly may lead to unknown failures in treatment efforts when finally applied.

5. Site-Specific Application Challenges

Water movement, turbulence, and system design can all impact how well a dispersant interacts with contaminants. In static or low-flow systems, dispersants may not reach the target material or may settle before adequate mixing, reducing effectiveness and leading to continued accumulation.

Troubleshooting Dispersant Application: Step-by-Step

When a chemical dispersant fails to perform as expected, effective troubleshooting requires a structured approach. The following steps help identify the root cause, improve treatment outcomes, and minimize downtime or environmental exposure.

1. Review Application Logs and System History

Start by gathering your operational log entries:

- What dispersant was used?

- How much was applied?

- What was the temperature and flow condition during application?

- Were other chemicals added concurrently?

Patterns in historical data can highlight inconsistencies in dosage, timing, or external conditions that impact performance.

2. Verify Dispersant Compatibility

Not all dispersants are designed for every contaminant. Review the product’s technical sheet or EPA registration (if applicable) to ensure it’s compatible with the target oil, grease, or residue type. Cross-reference any changes in raw materials or operating environment that may affect the product’s ability to interact with contaminants.

3. Assess the Method of Application

Dispersants require adequate mixing energy and surface contact to work. Check for:

- Clogged or misaligned spray nozzles

- Inadequate circulation pumps

- Improper spray angles or connection points

- Inconsistent dwell time or dispersion intervals

If needed, perform a field test with a marked control volume to observe dispersant spread and breakdown patterns.

4. Conduct Bench Testing or Jar Tests

A small-scale test can simulate in-system dispersant action. These tests help assess how well the dispersant performs with the current contaminant load, temperature, and water chemistry. This provides feedback that informs real-time dosing adjustments or reformulation choices.

5. Increase Monitoring and Visual Observation

Sometimes the issue lies in unmonitored drift, secondary accumulation, or product layering. Watch for surface sheen, foaming, or uneven disperse zones. Visual inspection during and after application can provide essential insights on whether the dispersant has distributed properly or if localized failure zones exist.

6. Evaluate for Environmental Interference

Are surfactants competing with naturally occurring organics, or is clay in the system affecting product efficiency? Check for external substances entering the system that may be neutralizing or absorbing the dispersant. External lab testing may be necessary in systems with unknown influents.

Learn more on our blog: Emulsion Breaking: Chemical Formulation Strategies That Work

Environmental and Human Considerations

While chemical dispersants are engineered to manage contamination efficiently, their use carries important environmental and human health implications. These concerns must be considered during selection, application, and evaluation stages of any treatment plan.

1. Environmental Impact

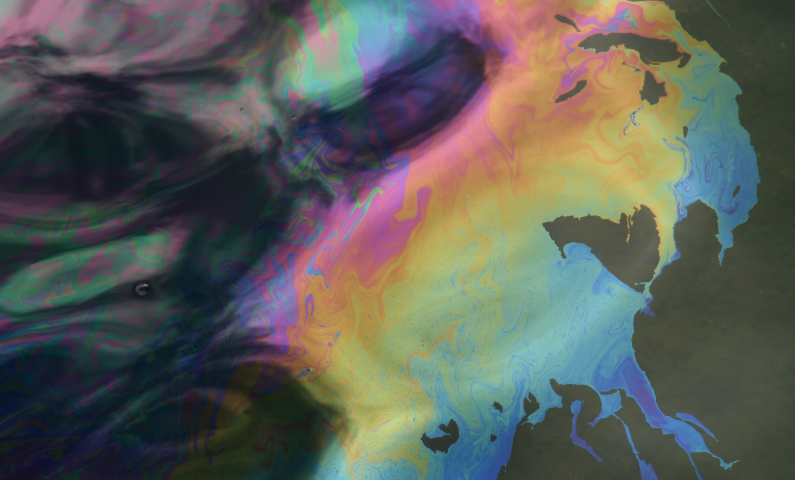

In marine and open water scenarios, dispersants can help prevent oil from forming large slicks on the surface, but they also introduce the pollutant deeper into the water column. This may expose aquatic life, such as fish and benthic organisms, to higher concentrations of toxic compounds. Some studies have shown that dispersants may increase the toxicity of oil by making hydrocarbons more bioavailable.

Additionally, dispersant residues can persist in sediments or interact with other substances, leading to long-term accumulation. Regulatory oversight, such as EPA guidelines, is in place to mitigate these outcomes, but not all sites fall under the same jurisdiction or scrutiny. In U.S. waters, any significant spill response involving dispersants must comply with federal plans and gov-issued safety protocols.

2. Human Safety and Exposure

For operators and field personnel, dispersant exposure can result in skin or respiratory irritation, particularly during high-volume or aerosolized application. It is essential to wear proper PPE and follow exposure limits detailed in safety data sheets. Additionally, accidental release of dispersants into potable water systems or direct human-use channels can raise serious risks, especially when product formulation details are unknown or not disclosed.

Site audits and hazard reviews are recommended to assess the safety of both the chemical used and the method of its delivery. All stakeholders — from plant technicians to environmental responders — should receive training on the effects and proper handling procedures for dispersants.

Example Case: Dispersant Challenges in the Gulf

A pivotal moment in public understanding of chemical dispersants occurred during the Deepwater Horizon oil spill in the Gulf of Mexico in 2010. As part of the response, over 1.8 million gallons of dispersants were applied to break up the massive oil slick before it reached sensitive shorelines. The goal was to reduce surface accumulation and allow natural microbial degradation in the water column.

While the strategy was partially successful, it also highlighted serious concerns about dispersant use on such a large scale. Some tested dispersants were found to be more toxic when mixed with crude oil than previously thought. The long-term effects on marine species, fish, and benthic communities became a point of scientific investigation and regulatory scrutiny. Communities in the Gulf also raised concerns about human exposure, particularly among cleanup crews and coastal populations.

Despite these challenges, the Gulf incident remains a valuable example of both the strengths and limitations of dispersant strategies. It showed that even effective dispersants can pose risks if applied without fully accounting for system dynamics, environmental sensitivities, and potential health impacts. It also emphasized the importance of having site-specific dispersant protocols and the need for continuous product evaluation.

How ETI Supports Effective Dispersant Use

When it comes to solving performance issues with chemical dispersants, ETI offers not only superior formulations, but also technical guidance and tailored treatment strategies built on decades of experience in particle and oil management.

Advanced Dispersant Technologies

ETI’s Advanced Dispersant Technologies are specifically engineered to prevent particulate buildup, maintain clean heat transfer surfaces, and improve overall system efficiency. These dispersants go beyond commodity chemicals by leveraging polymer engineering, targeted molecular weights, and optimized pH tolerance to perform under challenging industrial conditions.

For example, ETI offers:

- Cooling tower dispersants for high-hardness, fouling-prone systems

- Boiler dispersants that remain effective under extreme heat and pressure

- Closed-loop dispersants designed to protect low-flow areas

- Biodispersants that enhance biocide efficacy by penetrating biofilms

- Wastewater dispersants that aid in clarification and solid-liquid separation

Their performance monitoring protocols and ongoing optimization support allow facilities to troubleshoot problems quickly, adjust dosages, and validate dispersant effectiveness in real-time.

Oil Treatment Solutions

In tandem, ETI’s Oil Treatment services offer targeted solutions for removing emulsified oil and grease from wastewater. Their product suite includes:

- Emulsion breakers to split oil-water mixtures efficiently

- Oil-water separation agents that disperse hydrocarbons for better downstream removal

- Hydrocarbon absorbents to capture residual oil and protect system components

These treatments are ideal for industrial facilities facing recurring fouling, compliance issues, or equipment degradation due to oily waste streams. For operations experiencing chemical dispersant failures tied to oil loading or grease interference, ETI’s oil treatment program provides a parallel pathway to restore system balance.

The Science and Strategy Behind Dispersant Success

Dispersants play a vital role in maintaining clean, efficient, and compliant water systems. But like any chemical treatment, even the best chemical dispersant can fall short without the right application strategy, system awareness, and product selection. Whether the issue stems from environmental conditions, dosing inaccuracies, or chemical incompatibility, troubleshooting these challenges requires a careful balance of technical insight and operational discipline.

By understanding how dispersants work, identifying the common reasons for failure, and applying structured troubleshooting steps, operators can restore system performance and reduce long-term risks. Equally important is working with a trusted partner like ETI, whose advanced dispersant technologies and oil treatment solutions are tailored to meet the specific needs of industrial and environmental systems. Contact us today!

Frequently Asked Questions (FAQ)

How does clay in a water system affect dispersant performance?

Clays and other fine particulates can interfere with the action of a chemical dispersant by binding to active polymers or increasing the system’s total solids load. This reduces contact efficiency and may require adjusting the formulation or adding pre-treatment steps.

What should operators review when troubleshooting dispersant problems?

Operators should always review system logs, water chemistry, dosing records, and application points. Completing a full system audit ensures no connection or variable is overlooked that might impact dispersant effectiveness.

Are certain systems more susceptible to dispersant failure?

Yes, systems with stagnant zones, irregular flow, or frequent changes in contaminant load are more susceptible to dispersant underperformance. These systems may benefit from targeted application techniques or specialized formulations.

Can dispersant use help reduce compliance-related costs?

Absolutely. While high-quality dispersants may have a greater upfront cost, they often help reduce operational downtime, minimize environmental risks, and lower fines or cleanup dollars associated with non-compliance.

How can science-backed approaches improve dispersant strategy?

Incorporating water chemistry data, application modeling, and real-time monitoring allows teams to base decisions on proven science. Field testing has shown that custom dispersant programs significantly improve reliability and treatment success, especially when combined with targeted response protocols that act quickly.