In today’s industrial environment, reliable performance depends on more than advanced technology or automated dashboards. While monitoring systems are valuable tools for tracking water quality, chemical dosage, and system health, they are only part of the equation. True reliability comes when monitoring insights are paired with precise chemical control. Without the right chemistry, even the most sophisticated monitoring platform cannot prevent scale, corrosion, or contamination.

This connection between monitoring and chemistry is especially critical in regions like Pennsylvania and Ohio, where industries depend on stable water treatment to keep facilities operating efficiently. The blending, mixing, and delivery of the right industrial chemicals ensures that the data collected by monitoring systems translates into measurable results.

At ETI, decades of expertise in chemical blending support operators, engineers, and distributors by supplying tailored formulations that work hand-in-hand with monitoring. The result is long-term protection of assets, compliance with regulations, and improved operational efficiency across industries.

Why Monitoring Systems Alone Are Not Enough

Monitoring systems have become standard across industrial water and wastewater treatment. They provide operators with valuable data points, such as conductivity, pH, and total organic carbon levels, and they can flag potential problems before they escalate. Yet monitoring alone cannot solve the problem. It only identifies when conditions are drifting away from safe or efficient operating ranges. Without chemistry, those numbers remain passive information rather than actionable solutions. Consider the issue of corrosion in a boiler or cooling system. A monitor may detect oxygen levels rising or conductivity increasing, but unless the right blended chemicals are present, damage will still occur. The same is true in wastewater treatment, where monitoring can reveal organic contamination but only the correct chemical reaction can neutralize it.

Operators in industrial facilities are also aware that monitoring can give a false sense of security. A dashboard full of green lights does not necessarily mean that the right chemical control strategy is in place. Without consistent delivery of the correct chemistry, systems remain vulnerable to scaling, fouling, or compliance failures. This is why the relationship between monitoring and chemistry is inseparable. Monitoring systems provide the “eyes” to see what is happening in real time, but blended chemicals provide the “hands” that actually protect equipment and water quality. Together, they form a complete approach to operational reliability.

The Role of Chemical Control in Industrial Facilities

In any industrial facility, the bridge between monitoring data and operational success lies in effective chemical control. At its core, chemical control means ensuring the right concentration of industrial chemicals is applied at the right time and in the right location. It is the discipline that transforms monitoring data into protective actions for equipment, systems, and processes.

Safeguarding Water and Product Quality

When applied correctly, chemical control directly safeguards water quality and product quality. Examples include:

- Cooling towers: Scale inhibitors prevent calcium buildup that reduces heat transfer efficiency.

- Boiler systems: Oxygen scavengers remove dissolved oxygen before it accelerates corrosion of metal components.

- Wastewater treatment: Correct dosing neutralizes or precipitates contaminants, ensuring compliance with discharge regulations.

Each of these cases demonstrates how precise delivery of chemistry reduces risks, improves efficiency, and extends asset life.

Responding to Variability

The importance of chemical control is heightened by the variability of:

- Feedwater sources – changes in mineral content or contaminants

- Production demands – shifts in flow, pressure, or load

- Seasonal changes – temperature swings that alter corrosion or scaling potential

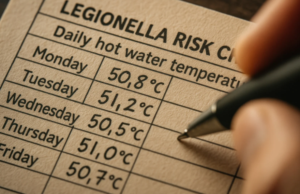

A monitoring system may show that pH levels are trending downward, but without an immediate and accurate chemical response, scaling, corrosion, or compliance failures can quickly follow.

A Cornerstone of Reliability

For operators and engineers across Pennsylvania and Ohio, chemical control is not just a technical function but a cornerstone of operational reliability. It aligns monitoring insights with measurable chemical actions. Without it, even the most advanced monitoring system becomes a reporting tool rather than a protective system.

Also read: How Industrial Wastewater Odor Control Systems Work

Understanding the Blending Process

Behind every successful chemical treatment program is a precise blending process. Blending is more than just combining ingredients, it is the careful preparation of different chemicals to create solutions that deliver consistent performance under real-world conditions. For water treatment professionals, this process ensures that monitoring data can be paired with chemistries tailored to a facility’s unique needs.

What Chemical Blending Means

Chemical blending is the controlled manufacturing and mixing of substances to create a reliable treatment product. It often involves combining raw materials such as polymers, inhibitors, dispersants, and neutralizers into blended chemicals designed for specific systems. The result is a finished product that can maintain its stability, provide accurate dosing, and meet regulatory standards.

Examples of Common Chemical Processes

While water treatment relies on highly specialized formulations, the concept of blending can be understood by looking at other industries:

- Cosmetics and soaps: Using oils, dry ingredients, and surfactants to create products with defined texture and consistency.

- Paints and pigments: Mixing compounds so that color, coverage, and durability remain uniform.

- Powdered detergents: A common chemical process where multiple materials are combined to improve cleaning power.

These examples show how blending ensures properties are controlled and predictable, whether in commercial or industrial applications.

Why Blending Matters in Water Treatment

- Consistency: Proper blending prevents uneven dosing that could compromise water quality.

- Properties and performance: The blending process ensures chemicals retain the right characteristics during storage and application.

- Efficiency: By combining components into many chemical blends, facilities save time compared to preparing individual treatments on-site, a task that can be time consuming and prone to error.

- Safety: Professionally developed blends reduce risks associated with handling raw or highly concentrated chemicals.

In essence, the blending process transforms raw ingredients into treatment products that monitoring systems can measure, verify, and optimize. It is where chemistry and operational practicality converge.

How Monitoring Enhances the Blending Process

Monitoring systems and the blending process are interdependent. Blended chemicals are designed with specific reactions in mind, but it is monitoring that verifies whether those reactions occur as intended. Without monitoring, operators are left to guess at system performance. Without blended chemistry, monitoring simply records problems without resolving them.

Turning Data Into Action

Modern monitoring platforms provide real-time analysis of parameters like pH, conductivity, and organic load. These values help operators determine whether adjustments are needed in chemical dosing. For example:

- A rise in conductivity may signal increased dissolved solids, prompting the need for scale inhibitors or adjustments to sodium hydroxide dosing.

- A spike in organic contamination could trigger dosing of oxidizing agents to protect operations and prevent compliance issues.

- pH readings trending outside target range may require immediate rebalancing with blended neutralizers.

Creating a Feedback Loop

When connected to a well-designed chemical control program, monitoring systems close the loop between data and chemistry:

- Input: Monitoring identifies deviations in system conditions.

- Response: Chemical control introduces targeted blends that correct those deviations.

- Verification: Monitoring confirms the correction and ensures the system remains within safe operating limits.

Optimizing Processes and Costs

This feedback loop is not only about system safety. It also ensures resources are used wisely. By confirming that chemical reactions are occurring as intended, operators can avoid over-dosing, reduce waste, and extend the lifespan of equipment. Monitoring thus enhances the process of chemical application, improving both performance and cost efficiency. Together, monitoring and blending transform industrial treatment from a reactive to a proactive discipline.

ETI’s Role in Linking Monitoring and Chemistry

For monitoring systems to deliver meaningful results, they must be supported by chemical programs designed to respond precisely to system data. This is where ETI stands apart. With nearly four decades of expertise, ETI develops advanced water treatment chemical blending capabilities that complement monitoring systems by ensuring the right chemistries are always available, stable, and optimized for your facility.

The Custom Formulation Advantage

ETI’s team doesn’t stop at mixing off-the-shelf chemicals. Through our custom formulation process, we analyze your system specifications, water chemistry, and operational constraints to engineer products that align with your monitoring program. This approach results in:

- Optimized performance for your specific water chemistry and metallurgy.

- Streamlined treatment, where multiple functions are combined into a single product.

- Reduced chemical usage, supported by accurate monitoring feedback.

- Consistent results, validated through ISO 9001-certified quality testing.

Supporting Operators and Distributors

ETI’s role is to serve as a partner, not a competitor. We supply blended chemicals that integrate seamlessly with monitoring platforms across boilers, cooling towers, closed loops, and wastewater systems. By combining chemical expertise with monitoring insights, ETI helps operators protect assets, improve compliance, and manage costs effectively. Ready to optimize your monitoring and chemical programs together? Contact ETI today to discuss tailored solutions for your facility.

Frequently Asked Questions (FAQs)

What is the main difference between chemical blending and chemical mixing?

Chemical blending is a controlled industrial process that ensures consistency, stability, and safety across batches. Chemical mixing may simply combine different chemicals without guaranteeing uniform properties in the finished product.

Why is monitoring important if blends are already created?

Monitoring ensures that systems operate correctly by confirming that chemical reactions occur as intended. It also helps eliminate contaminants, detect organic compounds at low levels, and maintain safety in the site environment.

Are blended chemicals dangerous?

Blended chemicals are designed to minimize risks, but like all toxic or flammable substances, they must be handled carefully. Each formulation is defined, created, and intended for a specific application. Proper training and monitoring reduce risks while protecting plants, operators, and the environment.

How do monitoring systems improve the effectiveness of chemical control?

Monitoring systems provide real-time data that help operators fine-tune chemical dosing. By detecting changes in pH, conductivity, or oxygen levels, these systems ensure that the right blending process and formulations are applied at the right time. This feedback loop reduces waste, improves efficiency, and ensures the chemistry performs exactly as intended.