Cooling tower systems play a critical role in modern industrial and commercial operations by enabling the efficient removal of unwanted heat from processes and equipment. These systems are widely used in industrial facilities, power plants, HVAC systems, and large air conditioning installations where excess heat must be rejected to maintain stable, energy efficient operation. By managing waste heat effectively, cooling tower systems support reliable performance, protect equipment, and help control operating costs across a wide range of applications.

At their core, cooling towers are a specialized form of cooling systems designed to transfer heat from warm water to the atmosphere. As heat energy is removed, cooled water can be recirculated back to heat exchangers, refrigeration systems, or air conditioning equipment. This continuous process allows facilities to maintain temperature control while minimizing energy consumption and supporting overall system efficiency.

Understanding how cooling tower systems function requires more than a basic knowledge of equipment. Design choices, operating conditions, and water treatment strategies all influence cooling efficiency, heat transfer performance, and long term reliability. Factors such as heat load, ambient conditions, and water quality interact throughout the entire system, making cooling towers a critical point where engineering, operations, and chemistry converge.

Fundamentals of Cooling Tower Operation

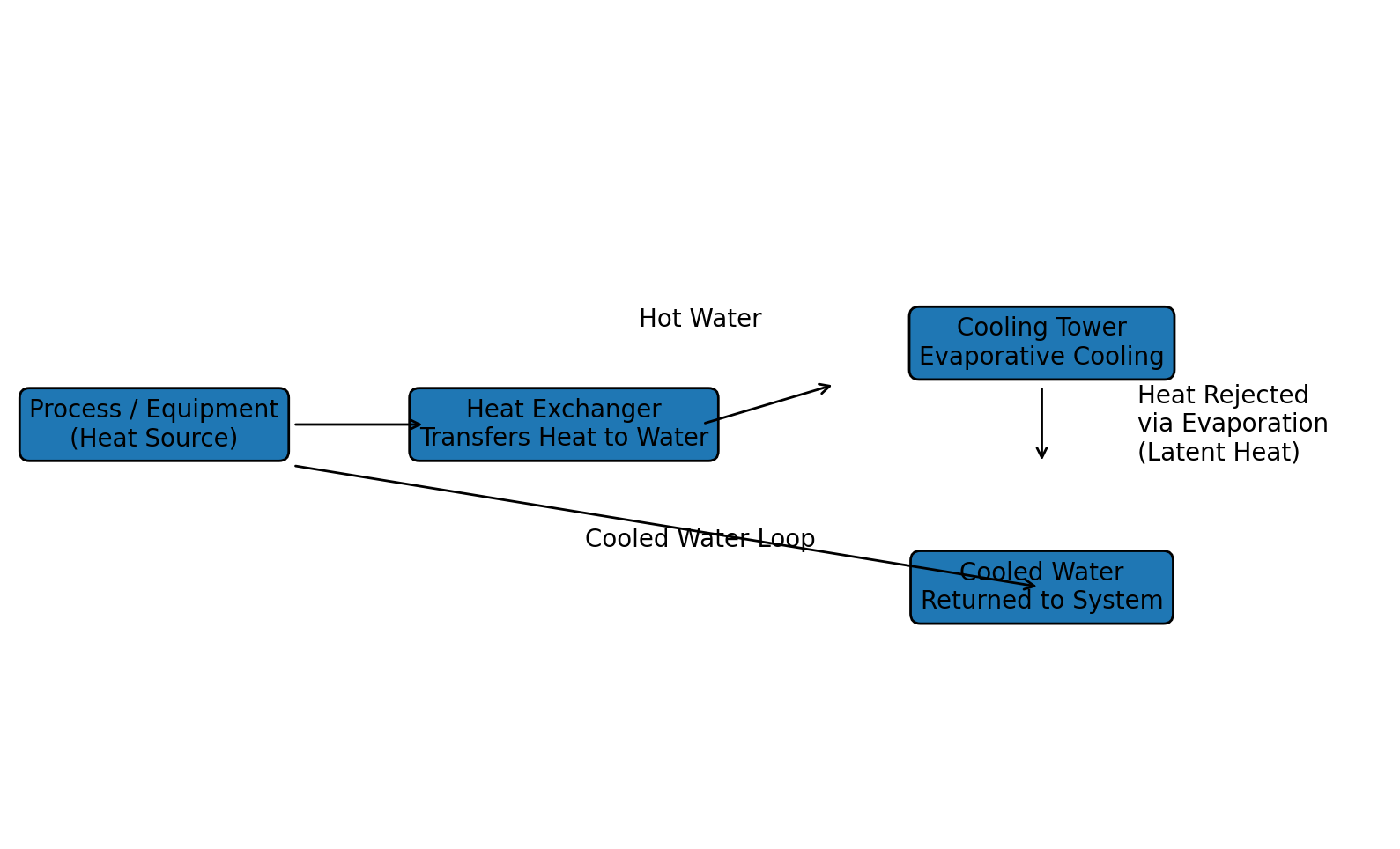

Cooling towers operate on the principle of evaporative cooling, a highly effective method for removing heat from water-based systems. In many industrial processes and HVAC applications, warm water absorbs heat from equipment, heat exchangers, or refrigeration systems. This warm water is then routed to the cooling tower, where the heat absorbed can be safely rejected to the atmosphere.

Inside the cooling tower, warm water is distributed over fill media or splash surfaces that increase the surface area available for heat transfer. At the same time, air is drawn or forced through the tower, creating direct contact between air and water. As a small portion of the water evaporates, latent heat is removed from the remaining water. This process allows the system to absorb heat efficiently and convert heat energy into water vapor that exits the tower with warm air.

The effectiveness of this process depends on maintaining proper contact between air and water. As hot water enters the tower, it encounters cooler, drier air. Heat absorbed by the water is transferred to the air stream, and the remaining water temperature is reduced. The cooled water then collects in the tower basin and is returned to the cooling system to repeat the cycle. This continuous loop enables cooling towers to remove heat reliably from processes that generate large amounts of unwanted heat.

In simplified terms, cooling tower operation follows a consistent sequence:

- Warm water enters the tower from the process or heat exchanger

- Air moves through the tower and contacts falling water droplets

- Latent heat is released as a portion of the water evaporates

- Cooled water is collected and recirculated back into the system

By relying on evaporation rather than mechanical refrigeration alone, cooling towers provide an efficient way to manage heat loads while supporting stable operation across a wide range of industrial and commercial applications.

Heat Transfer Principles and System Performance

In most cooling tower systems, heat transfer begins upstream at a heat exchanger, where process equipment, air conditioning equipment, or industrial machinery transfers heat to circulating water. This heated water then enters the cooling tower, where additional heat transfer occurs through evaporation. Unlike sensible heat transfer alone, evaporative cooling relies heavily on latent heat, making it far more effective at rejecting heat energy than air-only cooling methods.

Several environmental and operational factors influence how efficiently a cooling tower can remove heat. Wet bulb temperature is one of the most critical parameters, as it represents the lowest temperature water can theoretically reach through evaporation. When wet bulb temperature rises, the cooling capacity of the tower is reduced. Relative humidity, dry air conditions, and ambient air temperature all affect the ability of air to absorb moisture and heat, directly influencing heat transfer efficiency.

System performance is also shaped by the temperature difference between incoming hot water and the cooled water leaving the tower. A greater temperature difference generally improves heat transfer but may require higher airflow rates or increased water flow. If airflow, water distribution, or contact time is insufficient, reduced efficiency can occur, even when the cooling tower appears mechanically sound.

Key factors that influence heat transfer performance include:

- Heat load generated by the process or equipment

- Temperature difference between hot water and cooled water

- Airflow rate and quality of air-water contact

- Ambient conditions such as wet bulb temperature and relative humidity

When heat transfer is optimized, cooling towers can remove heat consistently, maintain stable operating temperatures, and support energy efficient operation across a wide range of cooling systems.

Types of Cooling Towers and System Configurations

There are several types of cooling towers, each designed to meet specific performance requirements, space constraints, and operating conditions. While all cooling towers rely on evaporative cooling to remove heat, differences in airflow design, structural configuration, and scale can significantly influence cooling efficiency and system performance. Selecting the right tower configuration depends on factors such as heat load, available footprint, energy consumption goals, and the needs of the entire system.

Common Cooling Tower Configurations

| Tower Type | Draft Method | Typical Applications | Key Characteristics |

|---|---|---|---|

| Natural draft cooling towers | Natural convection | Power plants, large cooling towers | Very tall structures, rely on buoyancy of warm air, high exiting air velocities |

| Forced draft cooling towers | Forced draft cooling | Industrial facilities, HVAC systems | Fans at air inlet, push air through tower, compact design |

| Induced draft cooling towers | Draft cooling tower | Most industrial and commercial cooling systems | Fans pull air through tower, stable airflow, high efficiency |

| Counterflow cooling towers | Mechanical draft | Industrial processes, petrochemical plants | Air flows upward against falling water, high heat transfer efficiency |

| Crossflow cooling towers | Mechanical draft | HVAC and process cooling | Air flows horizontally across water flow, lower fan energy |

| Hybrid cooling towers | Mechanical and dry cooling | Water conservation focused facilities | Combine wet and dry cooling to reduce water usage |

| Delta cooling towers | Mechanical draft | Space constrained industrial sites | Compact footprint, reduced drift, modular design |

Natural draft cooling towers rely on natural convection rather than mechanical fans. As warm air rises through the tower, cooler air is drawn in at the base, allowing heat to be rejected without significant electrical energy consumption. These systems are commonly used in power plants and other applications requiring very large cooling capacities.

Mechanical draft designs, including forced draft and induced draft cooling towers, use fans to control airflow. Forced draft cooling towers push air into the tower, while induced draft configurations pull air upward through the system. Induced draft designs are widely used due to their stable airflow patterns and improved cooling efficiency across varying operating conditions.

Specialized designs such as hybrid cooling towers and delta cooling towers address specific challenges related to water usage, space limitations, and environmental considerations.

Cooling Tower Design Considerations

Effective cooling tower design is essential for achieving reliable performance, efficient heat rejection, and long term system stability. Design decisions influence how well a cooling tower can handle variable operating conditions, maintain heat transfer efficiency, and support the needs of the entire system. Poor design choices can limit performance from the start, while well planned designs create flexibility for changing process demands.

Fill Media and Water Distribution

Fill media plays a central role in cooling efficiency by increasing the surface area available for heat transfer. By spreading water into thin films or droplets, fill media enhances direct contact between air and water. Designs may use splash fill or film fill, depending on water quality, fouling potential, and operating conditions. Pressurized nozzles and well designed distribution systems ensure even water flows across the fill, preventing dry spots that can reduce performance.

Airflow Patterns and Fan Design

Airflow management is another critical aspect of cooling tower design. Fans must deliver sufficient airflow to remove heat while minimizing energy consumption. The choice between forced draft cooling and induced draft designs affects air distribution, fan efficiency, and maintenance access. Proper airflow ensures that warm air is effectively discharged and replaced with cooler, drier air capable of absorbing additional heat energy.

Variable Flow and System Flexibility

Modern cooling systems often operate under variable flow conditions due to changing process loads or seasonal demand. Cooling towers must be designed to handle variable water flow without compromising performance. Flexible designs accommodate fluctuating water flows, maintain consistent contact between air and water, and support efficient operation across a wide range of conditions. When variable flow is not properly addressed, reduced efficiency and uneven cooling can occur throughout the system.

Operational Factors Affecting Cooling Efficiency

Even a well designed cooling tower can underperform if operational conditions are not properly managed. Day to day operation has a direct impact on cooling efficiency, energy consumption, and operating costs. Understanding how operating variables interact with tower design helps operators maintain stable performance and avoid unnecessary stress on cooling systems.

One of the most significant operational challenges is fluctuating heat load. Industrial processes, HVAC systems, and air conditioning demands rarely remain constant. As heat load increases or decreases, cooling towers must respond by adjusting water flows, airflow rates, or both. Systems that are not operated within their intended range may experience reduced efficiency, higher energy use, or uneven cooling across the tower.

Environmental conditions also influence performance. Changes in ambient temperature, relative humidity, and weather patterns affect the ability of air to absorb moisture and heat. Cold weather introduces additional concerns, including icing, reduced airflow, and mechanical stress. Without proper operating strategies, these conditions can compromise cooling efficiency and increase maintenance demands.

Common operational factors that affect cooling performance include:

- Variable process or seasonal heat loads

- Energy consumption associated with fan and pump operation

- Inadequate airflow or water distribution

- Cold weather operation and freeze protection requirements

By aligning system operation with design intent and environmental conditions, cooling towers can maintain reliable performance while minimizing energy use and long term operating costs.

Also read: The Hidden Costs of Poor Cooling Tower Chemical Treatment: A Chemical Blender’s Perspective

Water Balance, Usage, and Conservation

Water management is a central consideration in the operation of cooling tower systems. As cooling towers rely on evaporation to remove heat, water usage is unavoidable. Understanding how water moves through the system allows operators to manage efficiency, control costs, and support water conservation objectives without compromising performance.

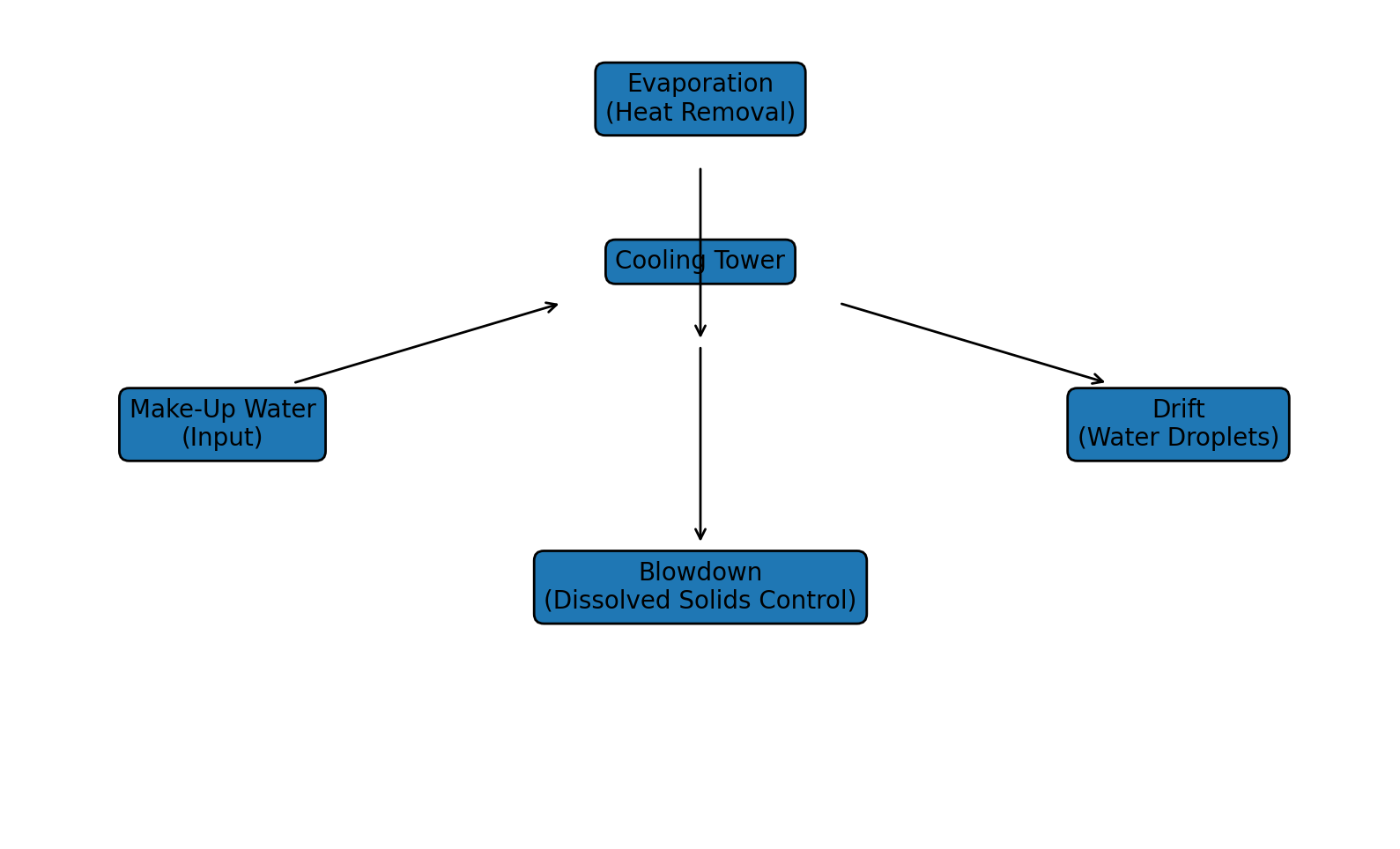

A cooling tower water balance accounts for all water entering and leaving the system. Make up water is added to replace losses that occur during normal operation. The largest of these losses is evaporation, which removes heat as water changes phase. Additional losses occur through blowdown, which is necessary to control dissolved solids, and through drift, where small water droplets exit the tower with exhaust air.

Key components of cooling tower water balance include:

- Make up water added to the system

- Evaporation losses as heat is rejected

- Blowdown used to manage dissolved solids

- Drift losses from entrained water droplets

As dissolved solids concentrate in tower water, excessive scaling, fouling, and corrosion can occur if blowdown rates are not properly controlled. Managing these concentrations protects heat transfer surfaces and supports stable operation. At the same time, excessive blowdown increases water usage and operating costs.

Water conservation efforts often focus on optimizing cycles of concentration, minimizing drift losses, and improving system control. Proper tower basin management, accurate flow measurement, and effective water treatment strategies all contribute to reducing water usage while maintaining reliable cooling performance. When water balance is well managed, cooling towers can operate efficiently while aligning with broader sustainability and resource conservation goals.

Applications Across Industries

Cooling tower systems are used across a wide range of industries where large amounts of heat must be removed to maintain process stability, equipment reliability, and energy efficient operation. Their ability to handle high heat loads and support continuous operation makes cooling towers a foundational component in many industrial and commercial cooling systems.

In power plants, cooling towers are essential for rejecting heat generated during electricity production. Large cooling towers are commonly paired with turbines and condensers to manage waste heat and maintain efficient energy generation. Natural draft cooling towers are frequently used in these environments due to their ability to handle extremely high heat loads with minimal auxiliary energy consumption.

Petrochemical plants and other industrial facilities rely on cooling towers to support critical industrial processes. Heat exchangers, reactors, and compressors generate significant heat that must be removed to protect equipment and maintain product quality. Cooling towers provide a reliable method for absorbing heat and returning cooled water to the process, even under variable operating conditions.

Common applications also include:

- Food processing plants, where cooling towers support refrigeration systems and temperature controlled production

- HVAC systems serving large commercial buildings and campuses

- Air conditioning equipment in facilities with high cooling demands

- Other industrial facilities that require continuous heat rejection

Cooling towers are also widely used alongside air cooled chillers and hybrid cooling systems, particularly where water usage or space constraints influence system selection. Regardless of application, the ability of cooling towers to remove heat efficiently and support stable operation makes them a critical component in modern cooling infrastructure.

Water Treatment and Maintenance for Cooling Towers

Effective water treatment is essential to the long term performance and reliability of cooling tower systems. Because cooling towers operate with warm water, open exposure to the atmosphere, and continuous evaporation, they create conditions where scale formation, corrosion, fouling, and biological growth can develop if not properly controlled. Without appropriate treatment and maintenance, these issues can significantly reduce heat transfer efficiency and increase maintenance costs.

As water evaporates in the cooling tower, dissolved solids remain behind and become concentrated in the tower water. If these solids are not managed, scale can form on heat transfer surfaces, restricting heat flow and increasing energy consumption. At the same time, corrosive conditions can damage metals throughout the cooling system, leading to leaks, equipment failure, and shortened asset life. Fouling from suspended solids and biological growth further reduces cooling efficiency by insulating surfaces and obstructing water flows.

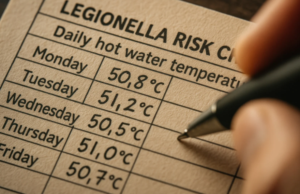

Biological control is a particularly important aspect of cooling tower maintenance. Warm water, direct contact with air, and nutrient availability create an environment where bacteria, algae, and other microorganisms can thrive. Effective water treatment chemicals are used to control biological activity, protect system cleanliness, and support safe operation. When biological fouling is not adequately controlled, heat transfer efficiency declines and the risk of operational disruptions increases.

A comprehensive water treatment program supports cooling tower performance by addressing several key objectives:

- Control of scale and mineral deposition

- Corrosion protection for system materials

- Management of biological growth and biofilms

- Preservation of heat transfer efficiency

- Reduction of unplanned maintenance and downtime

Routine monitoring, testing, and system inspections are essential components of effective maintenance. By combining sound operating practices with well designed water treatment strategies, cooling tower systems can reject heat efficiently, maintain consistent performance, and operate reliably over their intended service life.

Also read: Understanding Cooling Tower Chemistry: How to Select the Right Chemical Treatment Package

How Eastern Technologies, Inc. Supports Cooling Tower Programs

Reliable cooling tower systems depend on more than selecting the right chemistry. Program success comes from matching treatment technologies to real operating conditions, including heat load, makeup water quality, cycles of concentration, metallurgy, and the performance goals of the overall tower systems. Eastern Technologies, Inc. (ETI) supports water treatment professionals and OEMs with purpose-built cooling tower chemical treatment solutions, backed by technical expertise that helps partners improve efficient operation, protect assets, and manage risk.

ETI’s cooling tower treatment approach is built around three pillars that work together to keep heat transfer surfaces clean and performance stable:

- Scale and deposit control: ETI uses treatment technologies including phosphonate-based formulations and polymer dispersants to inhibit mineral deposition, disperse deposits, and stabilize minerals, including in higher-hardness or higher-cycle programs.

- Corrosion inhibition: Multi-metal protection packages help protect mixed metallurgy systems, including copper alloys, mild steel, aluminum, and galvanized surfaces. ETI also offers azole technologies for systems with critical copper components and varying pH conditions.

- Microbiological control programs: ETI supports oxidizing and non-oxidizing biocide options, plus biodispersants designed to disrupt biofilms and improve biocide penetration in rotation programs.

Beyond chemistry, ETI emphasizes application support so partners can implement and sustain results. That support can include system assessment services such as water analysis, metallurgy review, operational parameter evaluation, identification of fouling risks, and efficiency optimization opportunities, plus staff training and ongoing program adjustments as conditions change.

To learn more about ETI’s cooling tower chemical treatment solutions, contact us today.

Frequently Asked Questions (FAQs)

How does a cooling tower system work?

A cooling tower system works by removing heat from warm water through evaporative cooling. Hot water from a heat exchanger or industrial process enters the tower and is distributed over fill media, where it comes into direct contact with moving air. A small portion of the water evaporates, carrying away latent heat and cooling the remaining water. The cooled water collects in the tower basin and is returned to the system, while warm, moisture-laden air exits the tower. The process is influenced by wet bulb temperature and ambient conditions, which limit how much heat can be removed.

What are the three types of cooling towers?

Cooling towers are commonly grouped into three main types: natural draft cooling towers, mechanical draft cooling towers, and hybrid cooling towers. Natural draft cooling towers rely on natural convection and are typically very large structures used in power plants. Mechanical draft towers use fans to move air and include both forced draft and induced draft designs, which are widely used in industrial and commercial cooling systems. Hybrid cooling towers combine wet and dry cooling methods to reduce water usage while still providing effective heat rejection.

Why are we demolishing cooling towers?

Cooling towers are usually demolished when facilities are decommissioned, repurposed, or upgraded. Aging structures, ongoing corrosion, high maintenance costs, or changes in operational needs can make continued operation impractical. In some cases, cooling towers are removed to reduce long-term safety, environmental, or regulatory obligations, particularly when industrial sites are being retired or redeveloped.

How much does a 500 ton cooling tower cost?

The cost of a 500 ton cooling tower varies depending on design, materials, efficiency requirements, and site conditions. As a general planning range, equipment costs for a tower of this size often fall between approximately $150,000 and $500,000, with total installed cost influenced by accessories, controls, structural support, and local labor. Accurate pricing typically requires site-specific details such as wet bulb temperature, approach temperature, noise limits, and space constraints.