Legionella prevention is an essential part of protecting occupants, employees, and visitors in modern building water systems. Legionella bacteria are naturally present in freshwater environments, but when they enter engineered plumbing and mechanical systems, they can multiply under the right conditions and create serious health risks.

Legionnaires disease, a severe form of pneumonia caused by inhaling contaminated water droplets, has become a growing concern in facilities such as hospitals, hotels, office buildings, and large residential complexes. People with weakened immune systems, older adults, and those with chronic lung disease face an increased risk of infection when exposed.

Because building water systems include many interconnected components, including storage tanks, heaters, cooling equipment, and fixtures, facility managers must take proactive steps to reduce bacterial growth and minimize the likelihood of legionella contamination.

Effective prevention is not based on a single treatment or one-time fix. Instead, it requires a combination of proper maintenance, temperature control, disinfection practices, and water management planning. By understanding how Legionella spreads and where it thrives, building operators can implement practical strategies to safeguard public health and reduce exposure risks.

Understanding Legionella and How It Spreads

Legionella is a type of bacteria called Legionella that can cause serious respiratory illness when inhaled. Legionella infections most commonly occur when contaminated water becomes aerosolized water, meaning it is released into the air in tiny water droplets that people can breathe into their lungs.

Healthy people exposed to low levels of bacteria may not become ill, but individuals with weakened immune systems or underlying medical conditions often face more severe outcomes. In healthcare facilities, where vulnerable populations are present, controlling Legionella is especially critical.

The growth and spread of Legionella depends on specific environmental conditions. The bacteria thrive in warm water, particularly when water temperature ranges allow multiplication. Stagnant water, standing water in unused plumbing lines, and poorly circulated systems can all contribute to legionella growth.

Legionella exposure is most often linked to building-related sources rather than natural lakes or rivers. Common transmission pathways include:

- Shower heads and faucets releasing small droplets

- Cooling towers producing aerosolized mist

- Hot tubs and decorative fountains generating airborne spray

- Hot water tanks and storage systems that are not properly maintained

It is important to note that Legionnaires disease is not spread person-to-person in typical cases. Instead, prevention focuses on reducing legionella bacteria in water systems before they reach occupants.

By understanding these mechanisms, facility teams can better identify where risks exist and apply appropriate legionella control measures throughout their building water system components.

Why Building Water Systems Are High-Risk Environments for Legionella Growth

Building water systems create ideal conditions that can support legionella growth if they are not carefully designed, operated, and monitored. Unlike natural freshwater environments, engineered plumbing networks contain many areas where water can stagnate, warm up, or lose disinfectant protection over time.

Legionella bacteria multiply most easily when water temperature is within a favorable range and when water remains in the system for an extended period without sufficient flow. This is why both warm water and improperly managed cold water systems can become risk factors.

Several common conditions in building infrastructure can support bacterial growth:

- Stagnant water in underused fixtures or vacant areas

- Standing water in storage tanks or low-flow sections

- Dead legs, which are unused pipe segments where water sits undisturbed

- Low disinfectant residual, allowing microbes to persist

- Sediment, scale, or biofilm buildup, which protect bacteria from treatment

Many water system components, including valves, tanks, and recirculation loops, can unintentionally create pockets of reduced circulation. When water is not regularly refreshed, disinfectant levels decline and environmental conditions become favorable for Legionella.

Water quality is another key factor. The presence of organic material, corrosion products, or other bacteria can provide nutrients that help Legionella persist. In complex plumbing networks, cross contamination between system zones may occur if pressure changes or plumbing work disrupts normal flow.

Because building water systems are designed for comfort and convenience, such as delivering consistent hot water or maintaining cooling performance, they often operate in temperature ranges that overlap with bacterial risk zones. This makes routine monitoring and preventive planning essential, especially in healthcare facilities and other high-occupancy environments.

Ultimately, the goal is to minimize legionella growth by reducing stagnation, maintaining appropriate operating conditions, and ensuring systems remain properly maintained over time.

Also read: Reducing Legionella Risk: How Smart Chemical Blends Safeguard Industrial Water Systems

Key Locations Where Legionella Contamination Commonly Occurs

Legionella contamination is most likely to occur in areas where water is warm, aerosolized, or held for long periods. Facility managers should pay close attention to equipment and fixtures that generate water droplets or allow bacteria to multiply unnoticed.

Some of the most common sources include:

Cooling Towers

Cooling towers are one of the highest-risk sources because they circulate warm water and can release aerosolized water into the surrounding air. If cooling towers are not properly maintained, they can amplify bacterial growth and spread contaminated mist across large areas.

Hot Water Tanks and Water Heaters

Hot water tanks and water heater systems can support legionella growth when temperatures are too low or when sediment accumulates. These systems require careful balancing of hot water delivery, scald prevention, and bacterial control.

Showers and Faucet Fixtures

Shower heads are a frequent exposure point because they produce tiny water droplets that can be inhaled. Fixtures in rarely used areas are especially vulnerable due to stagnant water.

Hot Tubs and Spa Systems

Hot tubs create warm water conditions with constant aeration, making them ideal environments for bacterial growth if disinfectant residual is not maintained.

Decorative Fountains and Water Features

Decorative fountains can generate airborne spray and small droplets, creating potential exposure risks in public spaces.

Complex Plumbing Networks

Large buildings often contain long pipe runs, storage zones, and dead legs that increase the likelihood of stagnation. These areas require targeted flushing and inspection as part of proper maintenance.

Identifying these high-risk locations is a critical step in controlling legionella growth and implementing effective prevention strategies across building water systems.

Core Legionella Control Measures for Facility Operators

Effective legionella prevention requires a layered approach that addresses the conditions that allow bacteria to multiply and spread. Because Legionella thrives in warm, stagnant environments, control strategies must focus on limiting bacterial growth, maintaining system performance, and reducing exposure pathways.

The following legionella control measures are widely recognized as essential for building operators and water treatment teams:

Maintain Adequate Disinfectant Levels

A stable disinfectant residual helps prevent bacterial growth throughout a plumbing network. When disinfectant levels decline, Legionella and other bacteria can persist within biofilms and system deposits.

Operators should routinely verify that disinfectant levels are consistent at key points in the distribution system, especially in large or complex buildings.

Control Water Age and Reduce Stagnation

Stagnant water is one of the strongest contributors to legionella growth. Systems that sit unused for an extended period can quickly lose disinfectant protection.

Key practices include:

- Flushing rarely used outlets

- Removing dead legs during renovations

- Ensuring regular circulation in hot water loops

- Addressing low-flow areas where standing water may occur

These actions help minimize legionella growth by keeping water fresh and moving.

Manage Biofilm, Scale, and Sediment

Legionella bacteria often survive within biofilms, which form along pipe surfaces and protect microbes from disinfectants. Scale buildup and corrosion deposits can also provide nutrients that support legionella growth.

Routine cleaning, filtration, and targeted treatment programs help reduce legionella growth by limiting these protective environments.

Monitor High-Risk Equipment Closely

Equipment that generates aerosolized water requires extra attention, including:

- Cooling towers

- Hot tubs

- Decorative fountains

- Hot water tanks

These systems should be properly maintained according to manufacturer’s instructions and industry best practices.

Implement Testing and Response Protocols

While routine testing alone is not sufficient, sampling can support controlling legionella when paired with corrective action plans. If results indicate elevated levels, immediate response may include:

- System disinfection

- Temperature adjustments

- Increased flushing

- Review of operating conditions

The goal is always to control legionella growth before exposure occurs.

Overall, controlling legionella requires consistency. Prevention depends on combining treatment, monitoring, and proper maintenance into a repeatable program that reduces risk over time.

Water Management Programs and Industry Guidance

A structured water management program is one of the most effective tools for long-term legionella prevention in building water systems. Rather than relying on isolated fixes, water management programs provide an organized framework for identifying hazards, implementing controls, and verifying performance.

These programs are especially important in healthcare facilities, where patients may have weakened immune systems and face increased risk of severe infection.

A strong program typically includes:

- Identification of all water system components

- Assessment of areas that support legionella growth

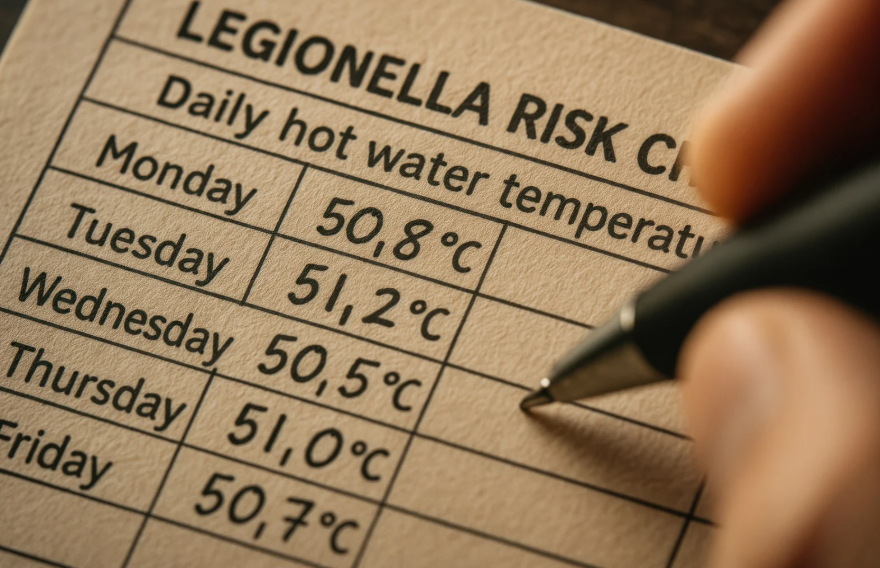

- Documentation of control limits for disinfectant residual and water temperature

- Routine maintenance schedules

- Response plans for abnormal conditions or positive test results

Industry organizations such as the American Industrial Hygiene Association and professional groups of air conditioning engineers have emphasized the importance of proactive disease control through formal planning and oversight.

In many jurisdictions, health department expectations increasingly require facilities to demonstrate that legionella control is being addressed systematically, not reactively.

Water management programs help ensure:

- Accountability across facility teams

- Ongoing verification of system performance

- Reduced likelihood of legionella contamination

- Better protection of public health

When properly implemented, these programs provide the structure needed to prevent Legionella from becoming established in building infrastructure and to minimize risk for occupants and visitors.

Temperature Control and Plumbing Best Practices

Water temperature management is one of the most important operational strategies to prevent legionella growth in building water systems. Legionella bacteria thrive in warm water conditions, particularly when temperatures remain in the range that supports multiplication.

Facilities should ensure hot water is stored at temperatures high enough to reduce bacterial survival, while also protecting occupants from scalding risk.

A key best practice is to install thermostatic mixing valves. Thermostatic mixing valves allow systems to maintain higher storage temperatures while delivering safe hot water at fixtures. This approach supports controlling legionella while also helping prevent scalding.

Additional plumbing strategies include:

- Maintaining adequate circulation in hot water loops

- Reducing heat loss in distribution piping

- Ensuring cold water remains cold and does not warm excessively

- Using point of use filters in high-risk areas, such as healthcare facilities

Point of use filters can provide an extra barrier at outlets such as shower heads, where legionella exposure risk is highest due to aerosolized water.

Together, temperature control, mixing valve installation, and fixture-level protections help minimize legionella growth and reduce exposure through tiny water droplets.

Maintenance, Monitoring, and Preventing Cross Contamination

Long-term legionella control depends on routine maintenance and continuous monitoring of water quality. Even well-designed systems can become vulnerable if operating conditions drift over time.

Facilities should prioritize:

- Scheduled flushing of low-use outlets

- Inspection of dead legs and stagnant zones

- Cleaning of cooling towers and storage tanks

- Maintaining disinfectant residual throughout the system

Cross contamination can occur when plumbing work disrupts flow patterns or introduces sediment into the system. Following manufacturer’s instructions during repairs and recommissioning is critical.

Extended periods of low occupancy, such as seasonal shutdowns, can also increase bacterial growth risk. In these situations, proactive flushing and system disinfection are often necessary to prevent bacterial growth and protect occupants.

Proper maintenance reduces legionella contamination risk while also improving overall system reliability.

How Eastern Technologies, Inc. Supports Legionella Control Efforts

Eastern Technologies, Inc. (ETI) supports independent water treatment professionals by providing the products, expertise, and technical resources needed to strengthen legionella prevention strategies.

Because effective legionella control measures require more than chemicals alone, ETI partners with distributors and service companies to help implement consistent water treatment approaches, monitoring support, and maintenance guidance across complex water systems.

ETI’s technical teams assist with:

- Cooling tower treatment and disinfection planning

- Hot water system operational support

- Water management program development resources

To learn more about ETI’s water treatment support services, visit ETI’s website.

Preventing Legionella Requires Proactive System Management

Preventing Legionella in building water systems is a critical responsibility for facility operators, healthcare providers, and water treatment professionals. Legionnaires disease can have severe consequences, especially for individuals with weakened immune systems or chronic lung disease.

Through structured water management programs, consistent temperature control, proper maintenance, and targeted monitoring, organizations can reduce legionella growth and protect public health.

Legionella prevention is most effective when it is proactive, documented, and built into daily operational discipline, rather than addressed only after contamination occurs. For organizations seeking additional technical guidance or support in developing effective legionella control measures, Eastern Technologies, Inc. (ETI) works alongside independent water treatment professionals to provide expertise, resources, and reliable solutions tailored to complex building water systems.

To learn more or speak with ETI’s technical team, contact Eastern Technologies, Inc. today to discuss your facility’s legionella prevention strategy.

Frequently Asked Questions (FAQs)

Where do legionella bacteria come from?

Legionella bacteria occur naturally in freshwater environments such as lakes and rivers, but they become a concern when they enter building water systems and find conditions that support legionella growth. Inside engineered plumbing networks, factors such as warm water, stagnant water, low disinfectant residual, and biofilm buildup can allow bacterial growth to increase. The bacteria called Legionella can then spread through water system components like hot water tanks, shower heads, and cooling equipment, creating a risk of legionella contamination and potential legionella exposure for building occupants.

How do cooling towers cause Legionnaires’ disease?

Cooling towers can contribute to Legionnaires disease when they are not properly maintained and allow legionella growth in warm circulating water. Because cooling towers release aerosolized water into the air, contaminated tiny water droplets can travel through ventilation or outdoor air currents and be inhaled by healthy people exposed nearby. This makes cooling towers one of the most important areas for controlling legionella, requiring routine maintenance, disinfection, and strong legionella control measures to minimize risk and prevent bacterial growth.

How common is it to get Legionnaires’ disease?

Legionnaires disease is considered relatively uncommon, but cases have increased in recent decades due to aging infrastructure, complex water systems, and greater awareness in public health monitoring. While most healthy people exposed do not become ill, individuals with weakened immune systems, chronic lung disease, or other underlying conditions face an increased risk of legionella infections. Because outcomes can be severe, especially in healthcare facilities, proactive legionella prevention through water management programs and proper maintenance remains essential even when overall case numbers are low.

Can you get legionnaires from a sauna?

It is unlikely to contract Legionnaires disease directly from a dry sauna, since Legionella primarily spreads through inhalation of aerosolized water rather than steam. However, facilities connected to saunas, such as hot tubs, showers, warm water pools, or poorly maintained water heaters, may present a risk if legionella contamination is present and water droplets become airborne. This is why controlling legionella growth across all connected building water system components, including nearby plumbing and fixtures, is important for disease control and minimizing legionella exposure.