Water hardness is a common challenge in industrial operations, especially those that rely on consistent water quality for heating, cooling, and process performance. Hard water contains high levels of dissolved minerals, primarily calcium and magnesium ions, which can accumulate inside equipment and reduce efficiency over time. Without proper control, these minerals contribute to scaling, buildup, and long-term maintenance issues across critical systems.

Implementing the right water hardness treatment strategy is essential for protecting industrial assets, improving operational reliability, and maintaining stable performance. From boilers and cooling loops to manufacturing processes, treating hardness helps facilities reduce costly downtime while supporting better overall water management. Understanding how hardness forms and how it can be addressed is the first step toward selecting the most effective treatment approach.

Understanding Water Hardness in Industrial Systems

Water hardness refers to the presence of hardness minerals in a water supply, most commonly caused by dissolved calcium and magnesium. These hardness ions enter fresh water as it moves through soil and rock, picking up calcium and magnesium salts along the way. The higher the concentration of these dissolved minerals, the more likely the water is considered water hard.

In industrial settings, hardness is typically measured in mg l (milligrams per liter) or grains per gallon, both of which help quantify the level of calcium and magnesium ions present. Identifying hard water early is important because very hard water can quickly lead to scaling, inefficiency, and equipment stress.

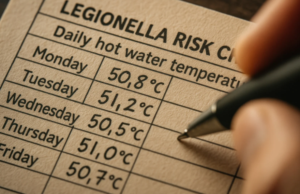

Professionals often evaluate hardness minerals through routine testing and monitoring, especially in systems where water usage is high. Understanding the balance of dissolved calcium and magnesium ions allows treatment teams to determine the best method for controlling buildup and maintaining consistent water quality across industrial processes.

Common Hard Water Problems in Industrial Use

Untreated hardness can create a range of operational challenges in industrial water systems. When calcium carbonate and other hardness minerals are heated or concentrated, they often form deposits that interfere with flow and performance.

Scale Buildup in Pipes and Equipment

One of the most common hard water problems is mineral buildup inside pipes, heat exchangers, and process lines. Over time, calcium carbonate deposits restrict water flows, reducing efficiency and increasing energy demand.

Reduced Performance in Water Heaters and Hot Water Systems

Hardness becomes especially damaging in heated applications. Water heaters and boilers exposed to hard water often experience faster scaling, which limits heat transfer and raises operating costs in hot water production.

Soap Scum and Residue Formation

Hard water also affects cleaning processes. Calcium and magnesium interact with soaps, forming soap curd and soap scum that can leave residue on surfaces and equipment. Tiny particles of mineral scale may also circulate through the system, contributing to additional wear.

Increased Maintenance for Industrial Appliances

Industrial appliances and system components exposed to hardness minerals require more frequent cleaning, descaling, and service, particularly when very hard water conditions persist.

Ion Exchange Water Softening

One of the most widely used water hardness treatment methods in industrial applications is ion exchange water softening. Traditional water softeners work by removing calcium and magnesium ions from hard water and replacing them with sodium ions or, in some cases, potassium ions. This exchange occurs inside a resin bed, where specially designed resin beads attract hardness ions as water flows through the system.

Over time, the resin becomes saturated with calcium and magnesium, requiring a regeneration process to restore its capacity. During regeneration, a brine solution made from sodium chloride, or salt, is drawn from a brine tank through a step known as brine draw. The brine flushes hardness minerals off the resin and replenishes it with sodium ions, producing soft water for continued use.

Ion exchange systems are highly effective for treating hard water problems in boilers, cooling loops, and other industrial operations requiring consistent water quality.

Lime Softening for High-Hardness Applications

Lime softening is another common method for removing hardness, especially in large-scale industrial water treatment programs. This process uses lime, typically calcium hydroxide, to chemically react with dissolved calcium and magnesium in the water supply. As the reaction occurs, hardness minerals form solid particles that can be separated through clarification and filtration.

Lime softening is often used when treating very hard water with high concentrations of magnesium salts or calcium carbonate. It is particularly effective for facilities with high water usage where treatment options must handle large volumes efficiently. While lime softening requires additional equipment and process control, it can significantly reduce hardness levels before further polishing methods are applied.

Reverse Osmosis and Filtration Approaches

Reverse osmosis is an advanced water hardness treatment option that removes dissolved minerals by forcing water through a semi-permeable membrane. This method is highly effective for reducing calcium, magnesium, and other impurities in industrial systems requiring high-purity water.

In many applications, reverse osmosis is combined with a water filtration system to capture particles, tiny suspended solids, and other contaminants before membrane treatment. These systems help improve overall water quality and protect downstream equipment.

Because water flows through the membrane under pressure, reverse osmosis is often selected for process water, specialty manufacturing, and facilities where consistent fresh water performance is essential.

Choosing the Right Treatment Option for Industrial Water Usage

Selecting the best approach to treat hard water depends on system goals, operating conditions, and total water usage. Many facilities use more water than expected across multiple loops and processes, so treatment selection should match both performance needs and flow demands.

Match the Method to the Application

A water softening system using ion exchange is often ideal for boiler feedwater and situations requiring consistent soft water. Lime softening can be a practical choice when the concentration of hardness is high and the facility needs a cost-effective solution at scale. Reverse osmosis is often selected when water treatment goals include broader removal of dissolved minerals and impurities.

Size the System for Flow and Volume

Treatment options should be evaluated against expected flow, total gallon throughput, and daily demand in liter terms where needed. Systems that are undersized can lead to unstable results and higher operating effort.

Consider Water Quality Targets and Operating Tradeoffs

Industrial teams often balance hardness reduction with overall water quality goals, operational simplicity, and maintenance requirements when choosing the right method.

How Eastern Technologies, Inc. Supports Industrial Water Treatment Professionals

Effective water hardness treatment often requires more than selecting a single method. Industrial systems can face scaling, corrosion, membrane fouling, and performance loss when dissolved minerals and impurities are not properly controlled. Eastern Technologies, Inc. (ETI) supports independent water treatment professionals with the chemistry, technical expertise, and operational reliability needed to manage these challenges.

ETI offers a broad portfolio of industrial water treatment solutions, including membrane antiscalants, biocides, boiler and cooling treatments, rust prevention programs, and scale remover formulations designed to restore flow and protect equipment. Partners also gain access to lab support, water chemistry studies, troubleshooting guidance, and flexible packaging options.

For expert support in selecting the right treatment options for your systems, contact ETI’s technical team today.

Frequently Asked Questions (FAQs)

What are 5 signs of hard water?

Common signs of hard water include soap scum on surfaces, soap curd left behind when using soaps, scale buildup in pipes and appliances, reduced efficiency in water heaters and hot water systems, and white mineral residue that is often cleaned with white vinegar. Many people use test strips to help with identifying hard water and measuring hardness in grains per gallon.

How do I lower water hardness?

Lowering hardness requires removing hardness ions such as dissolved calcium and magnesium ions. Treatment options include installing a water softener that uses ion exchange with sodium ions or potassium ions, applying lime softening for high-volume industrial process needs, or using reverse osmosis and a water filtration system to reduce dissolved minerals and impurities. Traditional water softeners rely on a resin bed and regeneration process using salt, brine, and a brine tank with brine draw cycles.

Does Mississippi have hard water?

Yes, many parts of Mississippi have hard water because groundwater sources contain higher levels of calcium carbonate and magnesium salts. Hardness levels vary by location, so reviewing local water quality reports is the best way to confirm hardness concentration.

Is it better to have hard or soft water?

Soft water is generally preferred because it reduces buildup, improves flow, and helps appliances operate more efficiently. Hard water can cause scaling in heated systems and increase maintenance, although softened drinking water may slightly raise sodium intake, so some facilities treat cooking water separately.