Alkalinity in water treatment is one of the most important concepts operators must understand because it influences nearly every part of a system’s performance. Whether you manage boilers, cooling towers, wastewater treatment processes, or drinking water systems, alkalinity helps stabilize water chemistry and supports reliable daily operations. Operators encounter fluctuations in water alkalinity due to changes in source water, industrial processes, and chemical reactions that occur inside treatment equipment. These shifts can affect corrosion, microbiological behavior, pH control, and the efficiency of critical treatment steps.

Alkalinity is more than a single number. It represents the water’s ability to resist a change in pH when acids enter the system. This buffering effect protects equipment and helps maintain the conditions necessary for healthy biological process performance, stable disinfection, and long-term asset protection. When alkalinity is not monitored or allowed to drift out of range, operational problems often follow, including scaling, acidic water conditions, and unpredictable swings in water pH.

This guide provides a practical explanation of alkalinity for operators. It outlines what alkalinity is, how it is measured, how it behaves in different treatment environments, and why consistent control matters. With a clearer understanding of alkalinity and its role in water treatment, operators can make informed decisions that support safer, more dependable facility operation.

What Is Alkalinity and Why Is It Important?

Alkalinity refers to the water’s ability to neutralize acids and maintain a stable pH. It is a measure of the acid neutralizing capacity of a water sample rather than an indicator of how alkaline or basic the water already is. This distinction is important because operators sometimes confuse alkalinity with pH. pH describes how acidic or alkaline water is at a given moment, while alkalinity describes the water’s capacity to resist a change in pH when acids or acidic compounds enter the system.

Most alkalinity in natural and industrial water comes from the presence of bicarbonate ions, carbonate ions, and small amounts of hydroxide ions. These ions act as buffering agents and help maintain stable conditions in treatment systems. In many types of source water and soils, bicarbonates are the dominant form, although carbonates and hydroxides become more significant when operators adjust chemistry or when water reacts with certain compounds during treatment.

How Alkalinity Is Measured in Water Treatment

Accurate testing is essential for maintaining stable system chemistry. Understanding how alkalinity is measured helps operators react quickly to changes and ensure reliable performance across treatment processes.

Common Methods for Measuring Alkalinity

Alkalinity is usually measured through a simple titration procedure known as an alkalinity test. During this test, an operator adds a standard acid solution to a water sample until the pH reaches specific endpoints. The amount of acid required to reach these points reveals the alkalinity values present in the water. This process is the standard approach used to determine alkalinity in field and laboratory settings.

p-Alkalinity and Phenolphthalein Endpoint

One important measurement is p alkalinity, which represents alkalinity measured to the phenolphthalein endpoint, usually around pH 8.3. This endpoint indicates the presence of hydroxide and carbonate alkalinity. Tracking p alkalinity helps operators understand how much of the buffering system is available in the stronger alkaline forms.

Total Alkalinity and the Methyl Orange Endpoint

To find total alkalinity, the titration continues to a lower pH, typically near 4.5, where bicarbonate alkalinity is also neutralized. This final value reflects the full acid neutralizing capacity of the water. Total alkalinity is an important measurement because it summarizes how effectively the water can resist a change in pH.

Instrumentation: pH Meters and Probes

Although alkalinity is not the same as pH, pH meters and a properly calibrated pH probe are essential tools during titration. Operators use pH readings to identify each titration endpoint and to monitor changes in pH that may signal the need for testing. A sudden change in pH during normal operation can indicate shifts in the buffering system and the need to perform an alkalinity test.

When Operators Should Determine Alkalinity

Alkalinity should be measured regularly in systems where pH stability is critical, such as boilers, cooling towers, and wastewater treatment units. Operators also determine alkalinity when source water conditions change or when large additions of chemicals may affect the carbonate system. Routine testing ensures reliable control and gives early insight into developing operational issues.

Also read: Chemical Options for Alkalinity Control in Water Treatment

Sources of Alkalinity in Industrial Water Systems

Understanding where alkalinity comes from helps operators predict how water will behave during treatment. Different sources contribute varying levels of carbonate, bicarbonate, and related ions, leading to different operational impacts.

Natural Sources in Groundwater and Surface Water

Most alkalinity in source water originates from geological formations. As water moves through soils and rock layers, it dissolves minerals that release carbonate and bicarbonate ions. Areas with limestone formations often produce water containing significant amounts of calcium carbonate, which increases natural buffering capacity. Even tap water may carry these ions depending on the mineral content of the watershed or aquifer.

In regions where rainfall, vegetation, or soil chemistry are acidic, alkalinity may remain low. Operators must account for these variations when assessing raw water chemistry because small amounts of natural buffering can lead to greater instability in industrial systems.

Industrial and Treatment-Related Sources

Industrial processes can introduce additional alkalinity. Some facilities use chemicals that break down into carbonate species or contribute hydroxide ions that influence the buffering system. In other cases, alkalinity increases during treatment steps where compounds are added to adjust pH, aid coagulation, or stabilize water quality.

Cooling systems, boilers, and wastewater plants sometimes require large amounts of treatment chemicals that influence alkalinity, while other systems only need small amounts to maintain consistent conditions. Monitoring these changes ensures that alkalinity remains within the recommended range for each process.

Chemical Addition as an Alkalinity Source

Operators often adjust alkalinity intentionally. Common chemicals include calcium carbonate, sodium bicarbonate, sodium carbonate, lime, and magnesium hydroxide. These compounds dissolve into carbonate or hydroxide ions and directly increase the water’s buffering capacity. Because each chemical behaves differently in solution, operators must consider solubility, reaction speed, and compatibility with equipment and system chemistry when selecting an alkalinity source.

Operational Impacts: Why Operators Must Control Alkalinity

Controlling alkalinity is essential for stable treatment performance. When alkalinity drifts too low or too high, operators can experience problems that affect water quality, equipment condition, and overall system reliability. Understanding these impacts helps facilities maintain safe and consistent operation.

Alkalinity, pH Control, and Acidity Management

Alkalinity plays a direct role in how water responds to acids produced by natural reactions and industrial processes. Systems with adequate buffering capacity are better able to resist sudden changes in pH, which protects equipment and supports consistent treatment results. When alkalinity is low, acidic water can form quickly. This increases the risk of corrosion, reduces the effectiveness of certain chemicals, and causes instability in many operating environments.

Corrosion, Scale, and High or Low Alkalinity Conditions

Low alkalinity allows acidity to rise, which can attack metal surfaces and shorten the lifespan of pipes, tanks, and heat-transfer equipment. On the other hand, high alkalinity can lead to scaling and the precipitation of hardness minerals. These solids settle on heat-exchange surfaces and reduce efficiency in boilers and cooling systems. Excessive alkalinity also interferes with disinfection steps by reducing the effectiveness of chlorine, which may leave unwanted compounds present in the water.

Impacts on Biological Processes in Wastewater Treatment

In wastewater treatment, alkalinity acts as a supporting resource for bacteria responsible for nitrification and anaerobic digestion. These biological processes consume alkalinity as they convert ammonia to nitrate or break down organic material. Without sufficient alkalinity, pH can fall to levels that inhibit bacteria, slow treatment performance, and cause incomplete reactions. Maintaining proper buffering capacity ensures that microorganisms remain active and stable throughout the process.

Interactions With Ammonia, Nitrate, and Other Compounds

Alkalinity directly influences how nitrogen compounds behave in treatment systems. The conversion of ammonia to nitrate requires consistent pH, and alkalinity helps maintain the environment needed for these conversions. In systems where acidity rises, operators may see incomplete nitrification or greater concentrations of ammonia. These changes can affect effluent quality and lead to compliance challenges if not corrected promptly.

Impact on Water Quality and Equipment Health

Stable alkalinity improves overall water quality by preventing wide swings in water pH and reducing the formation of corrosive or acidic conditions. It also helps keep equipment surfaces clean by limiting precipitation reactions that produce scale. By monitoring alkalinity regularly, operators can address issues early and maintain the health of pumps, pipes, vessels, and other infrastructure components.

Also read: Chelating Agents in Heavy Metal Removal: Selection and Application

Alkalinity in Different Water Treatment Processes

Alkalinity influences a wide range of water treatment processes. Each system interacts with carbonate, bicarbonate, and hydroxide chemistry in different ways, so operators must understand how alkalinity affects performance in the environment they manage.

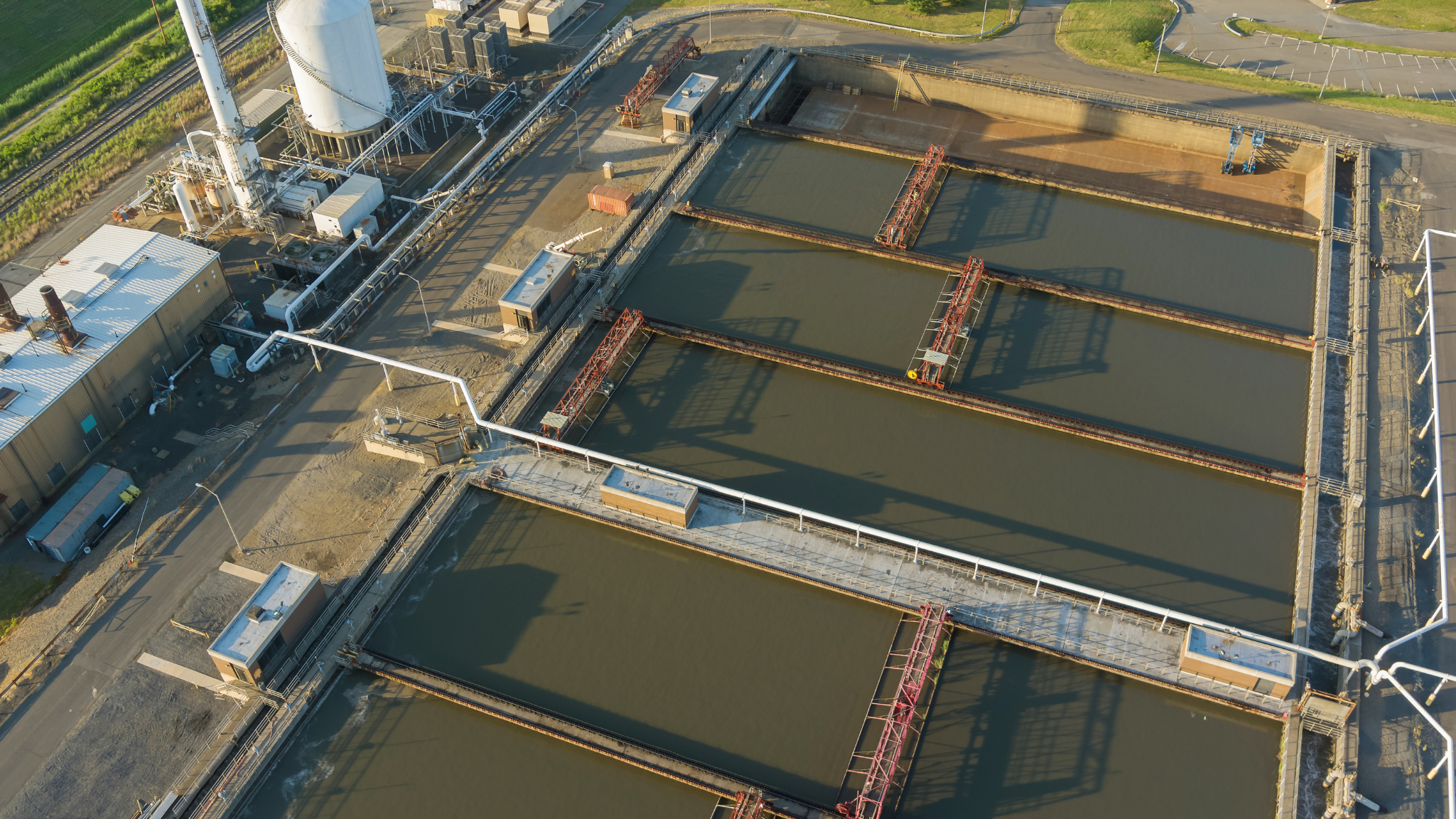

Alkalinity in Wastewater Treatment Systems

Biological wastewater treatment relies heavily on stable alkalinity. As bacteria convert ammonia to nitrate, they consume alkalinity and release acids that lower pH. If buffering capacity is too low, the biological process slows, and operators may see increases in ammonia, incomplete nitrification, or foaming. Maintaining consistent alkalinity supports the efficiency of treatment basins, clarifiers, and anaerobic digestion units that depend on predictable chemistry.

Alkalinity and Drinking Water Treatment

In drinking water applications, alkalinity affects coagulation, filtration, and disinfection. Water with very low alkalinity can experience rapid pH swings when aluminum or iron coagulants are added, which may reduce their effectiveness. Chlorine also behaves differently depending on pH, so a stable level of alkalinity helps maintain predictable disinfection results. Operators working with surface water or municipal supplies often adjust chemistry to preserve stable conditions.

Reverse Osmosis and Membrane Systems

Reverse osmosis systems require careful alkalinity control because carbonate and bicarbonate ions can form scale on membrane surfaces. When water encounters high pressure in an RO unit, minerals may precipitate if the conditions exceed their solubility. Adjusting alkalinity helps limit carbonate scale formation and protects membranes from early fouling. Proper chemical selection is critical because even small changes in carbonate alkalinity can influence membrane performance.

Boilers, Cooling Towers, and Industrial Processes

Boilers depend on alkalinity to neutralize acids that form inside the system. However, high alkalinity can create foaming or carryover, and excessive hydroxide ions may lead to corrosion under deposits. Cooling towers also require balance because carbonate and bicarbonate ions interact with hardness minerals to precipitate solids. In many industrial processes, alkalinity influences reaction rates, material compatibility, and the stability of treatment chemicals. Maintaining the correct alkalinity level provides a stable chemical environment that supports consistent system operation.

Interaction With Chemical Addition and Treatment Goals

Throughout all treatment processes, chemicals such as lime, sodium carbonate, magnesium hydroxide, and caustic soda are used to adjust buffering strength. Each chemical affects alkalinity differently, so operators must understand how these additions shift the carbonate system. Matching chemical addition to system goals ensures that alkalinity supports rather than disrupts treatment performance.

Adjusting Alkalinity, Chemical Addition and Operational Strategies

Maintaining the right level of alkalinity requires a combination of chemical addition and consistent monitoring. Operators adjust alkalinity to support pH control, protect equipment, and maintain stable chemical conditions across treatment systems.

Common Chemicals Used to Adjust Alkalinity

Several chemicals are routinely added to increase alkalinity and strengthen buffering capacity. Each compound contributes different ions and reacts at a different speed:

- Calcium carbonate provides a gradual increase in carbonate alkalinity and helps stabilize systems that need controlled adjustments.

- Sodium bicarbonate releases bicarbonate ions and is widely used when only moderate changes are needed.

- Sodium carbonate raises alkalinity more quickly and can increase pH when additional carbonate ions are required.

- Magnesium hydroxide supplies hydroxide ions and produces strong buffering capacity without a rapid jump in pH.

- Lime or caustic soda may be used for rapid pH control in systems that require immediate correction.

Because each solution reacts differently, operators must select chemicals that support treatment goals without causing large or sudden shifts in water chemistry.

Avoiding Sudden Changes in pH

Adding chemicals too quickly can result in a high pH that destabilizes treatment processes. A large amount of hydroxide or carbonate introduced at one time can cause precipitation reactions or interfere with downstream equipment. To avoid these problems, operators typically add chemicals in small, controlled doses. Maintaining a steady adjustment rate helps the system resist shock and supports predictable pH behavior.

Maintaining a Balanced Carbonate System

Balanced alkalinity supports the ability of water to resist changes in pH and limits the formation of scale or corrosive conditions. Operators should consider the presence of hardness, dissolved minerals, and process chemicals when adjusting alkalinity. Monitoring ensures that the carbonate system stays within the recommended range and provides reliable buffering capacity throughout the treatment process.

Operational Strategies for Long-Term Stability

A combination of frequent testing, gradual chemical addition, and careful control of make-up water helps operators maintain stable alkalinity levels. Adjustments may be required when source water conditions change, new chemicals are introduced, or system demands increase. Consistent attention to alkalinity ensures smoother operation and reduces the likelihood of issues caused by imbalance.

How ETI Supports Operators in Managing Alkalinity

Managing alkalinity effectively requires more than routine testing. It depends on selecting the right chemistry and applying it with precision. ETI supports operators by providing solutions that stabilize water systems, protect equipment, and improve overall treatment performance. With decades of experience in industrial water chemistry, ETI helps facilities maintain the balance needed to support reliable operation.

Engineered Alkalinity Boosters for Industrial Systems

ETI offers a range of alkalinity boosting solutions designed to strengthen buffering capacity and support predictable pH control. Unlike general-purpose caustic products, ETI’s blends are developed to provide controlled alkalinity increases without causing sudden or excessive shifts in water pH. These custom formulations help neutralize acids that form during operation and maintain stable conditions across boilers, cooling towers, and process systems.

For operators who want to learn more, ETI provides a detailed guide on its specialized formulations here: Explore ETI’s Alkalinity Boosters

Support for Corrosion Control and Scale Prevention

Alkalinity directly affects corrosion rates and scaling tendencies. ETI’s solutions are engineered to work in conjunction with existing corrosion inhibitor programs. By maintaining consistent alkalinity, operators can limit the formation of corrosive conditions and reduce the risk of calcium carbonate precipitate. Stable alkalinity helps protect equipment surfaces and supports the long-term health of pipes, heat exchangers, and other components.

Process-Specific Formulations for Industrial Applications

Different systems require different chemical characteristics. ETI provides alkalinity solutions tailored to:

- Boiler systems, where alkalinity must remain stable under high temperature and pressure

- Cooling towers, where operators must balance deposition control with reliable corrosion protection

- Process water systems, where pH boosters must avoid introducing interfering ions

- Wastewater treatment units, where stable buffering strengthens nitrification and improves biological performance

These application-specific options help operators maintain the precise conditions required for each treatment process.

Ongoing Support and Optimization

Water chemistry changes with seasonal conditions, operational demands, and equipment aging. ETI works directly with operators to evaluate system trends, refine alkalinity targets, and adjust chemical programs as conditions shift. This continuous improvement approach ensures that alkalinity remains within optimal ranges and that water treatment strategies align with the evolving needs of each facility.

If your facility requires expert guidance or a customized alkalinity program, contact ETI today to speak with a water treatment specialist.

Frequently Asked Questions (FAQs)

Why is alkalinity considered an indicator of water stability?

Alkalinity reflects the water’s ability to resist a change in pH when acids are introduced. This buffering capacity protects equipment, supports biological treatment, and prevents operational issues such as corrosion or scaling. When alkalinity values drop, water becomes more sensitive to acidic conditions, which can disrupt treatment processes.

Can alkalinity affect pipes and equipment lifespan?

Yes. Low alkalinity can lead to acidic conditions that damage metal surfaces and accelerate corrosion inside pipes and heat-transfer equipment. High alkalinity can also create conditions that promote scale formation. Maintaining the proper range helps protect infrastructure and ensures long-term system reliability.

How does alkalinity influence fish, wildlife, or discharged water?

Effluent with extremely low alkalinity can create acidic environments that stress fish and aquatic organisms. Stable alkalinity supports balanced water chemistry and healthier receiving waters, especially in facilities that must meet environmental discharge standards.

Does high alkalinity cause problems in reverse osmosis systems?

High alkalinity increases the risk of carbonate precipitation on membranes. Carbonate scale can reduce permeate flow, increase pressure requirements, and shorten membrane life. Operators typically adjust alkalinity before water enters RO units to protect membrane surfaces.

How does alkalinity interact with chlorine during disinfection?

Chlorine’s effectiveness depends on pH, which is stabilized by alkalinity. When alkalinity is too low, pH can drop rapidly during chlorination, reducing disinfectant performance. Adequate buffering ensures chlorine remains in its optimal form and maintains strong disinfection capability.