Every industrial water system relies on carefully balanced chemistry to stay efficient. Among the most important yet often overlooked processes are oxidation reduction reactions—the core type of chemical reaction that keeps boilers clean, cooling towers stable, and wastewater operations compliant. In simple terms, these are chemical reactions that involve the transfer of electrons between two species. One substance loses electrons through oxidation, while another gains them through reduction.

In the field, operators see this balance every day when oxygen removes contaminants or when a treatment chemical neutralizes metals. Each redox reaction changes the oxidation condition of the substances involved, influencing corrosion potential, scaling tendency, and biological growth. Understanding oxidation and reduction at this level is no longer optional—it is essential for achieving reliability and minimizing downtime.

This article explains how precise control of these reactions can directly improve plant performance. It also shows how ETI’s expertise in chemical blending helps facilities turn complex chemistry into consistent uptime and measurable energy savings.

Redox Basics for Operators

In everyday plant operations, redox chemistry appears constantly — whenever oxygen removes contaminants, chlorine neutralizes sulfides, or metals change form during filtration. Each of these processes depends on oxidation reduction reactions, which are chemical exchanges involving the transfer of electrons between two species.

Oxidation and Reduction in Simple Terms

An oxidation reaction occurs when a substance loses electrons, while a reduction reaction occurs when a substance gains them. The chemical that donates electrons is the reducing agent, and the one that accepts them is the oxidizing agent. Because one cannot occur without the other, oxidation and reduction occur together as part of the same redox reaction.

Understanding Oxidation Numbers

Each atom or ion has an oxidation number, or oxidation state, that represents how many electrons it has lost or gained compared to its neutral form.

- If an atom’s oxidation number increases, it has been oxidized.

- If its oxidation number decreases, it has been reduced.

Operators use these values to determine the oxidation state of key elements in a process. By checking that the sum of the oxidation numbers in a compound matches its expected charge, they can verify whether reactions are balanced and progressing correctly.

Real-World Relevance

The same chemistry applies across systems:

- Iron oxidation (Fe²⁺ → Fe³⁺) confirms filtration efficiency.

- Oxygen reacting with organics drives biological treatment and respiration, combustion, and corrosion processes.

- Chlorine neutralizing sulfides demonstrates a textbook oxidation reaction that maintains effluent clarity and odor control.

Recognizing oxidizing and reducing agents and tracking their number of electrons exchanged equips operators to maintain balance, optimize dosing, and prevent system upsets.

Oxidation States in Practice

For operators, the concept of oxidation states moves from theory to action every time a plant system is adjusted. The oxidation state—sometimes called the oxidation number—shows how many electrons a molecule, atom, or ion has lost or gained in a chemical reaction. Understanding this number helps determine which substances should be dosed, neutralized, or monitored more closely.

Quick Rules for Assigning Oxidation States

In most cases, the following guidelines make it easy to evaluate chemical behavior:

- Free elements have an oxidation state of 0.

- The sum of the oxidation numbers equals zero in a neutral compound and matches the ion charge in an ionic compound.

- Group 1 metals generally have an oxidation state of 1, and Group 2 metals have an oxidation state of 2.

- The oxidation state of oxygen is usually –2, except in peroxides such as hydrogen peroxide, where oxygen’s value changes because of its unique electron pairing.

- When determining the oxidation state in more complex compounds, balance each atom’s contribution until the overall charge matches expectations.

Applying the Rules in Real Systems

When metal ions, such as iron or manganese, shift between oxidation states, operators can directly observe the effect on color, clarity, or scale formation. By determining the oxidation state of dissolved metals, treatment professionals can decide whether to feed an oxidizing chemical like chlorine or ozone, or a reducing chemical such as sulfite or bisulfite.

Tracking oxidation states ensures that reactions run to completion, prevents overfeeding, and stabilizes process chemistry. In other words, understanding how an ion changes by gaining or losing electrons allows operators to correct a system before downtime occurs, rather than reacting afterward.

Half Reactions and Mass Balance

In every redox process, there are two halves of the same event—one losing electrons, the other gaining them. These are called half reactions, and together they describe the complete flow of energy and matter in oxidation reduction reactions. Understanding these halves helps operators verify that plant systems remain balanced and efficient.

The Two Halves of a Redox Reaction

- The oxidation half reaction shows the part of the system that loses electrons. This is where the oxidized half loses electrons, increasing its oxidation number.

- The reduction half reaction shows the substance that gains those electrons. This is the reduced half that gains electrons, lowering its oxidation number.

Because electrons cannot disappear or appear spontaneously, both halves occur together. The number of electrons lost in one part of the process must equal the number gained in the other. This principle ensures that matter and charge remain in balance.

Why Half Reactions Matter in Operations

In industrial water systems, half reactions are more than just chemical notation—they describe real performance data. When a chlorine-based oxidant reacts with sulfide, the oxidation step shows chlorine’s oxidation number increases as it donates electrons, while the reduction step shows sulfur’s oxidation number decreases as it is converted to sulfate.

In laboratory titrations and field sensors like ORP probes, operators indirectly monitor these half reactions. A rising ORP value often signals that oxidation is dominant, while a falling value suggests reduction is occurring. This alignment between oxidation reduction reactions and sensor readings allows staff to fine-tune aeration, feed rates, and reaction endpoints with confidence.

Operational Levers, ORP, Lab Tests, and Feed Control

Translating chemistry into real-world control begins with monitoring. In oxidation-reduction management, the most useful measurement is the oxidation reduction potential (ORP)—a field indicator of whether a sample environment is oxidizing or reducing. This reading connects directly to how oxidation reduction reactions progress in a process stream.

Monitoring and Interpretation

An ORP sensor measures the balance between oxidized and reduced species in millivolts.

- Positive ORP values signal oxidizing conditions, where species such as oxygen, ozone, or chlorine dominate.

- Negative ORP values suggest a reducing environment, often driven by organics, ammonia, or sulfides.

Laboratory verification complements field data. Operators confirm results through titrations or spectrophotometric tests, validating that the number of electrons exchanged matches the expected oxidation state changes. These checks ensure that the oxidation and reduction processes in the system remain balanced and efficient.

A steady ORP trend confirms that the oxidized half loses electrons at the same rate that the reduced half gains electrons. A sudden shift indicates that one half of the redox reaction is incomplete or that reagents are exhausted.

Common Chemical Scenarios

Many reactions monitored by ORP are easy to visualize:

- Hydrogen peroxide oxidation: The reaction of hydrogen peroxide decomposes into water and oxygen, showing both oxidation and reduction within one compound.

- Chlorine disinfection: Chlorine acts as an oxidizing agent, donating electrons to pathogens and contaminants until the oxidation number increases and the reaction completes.

- Metal precipitation: Iron and manganese control rely on redox shifts; when the oxidation state of oxygen changes in the reaction, insoluble oxides form that can be filtered out.

- Combustion and corrosion reactions: Although combustion reactions typically involve gases and heat, the same electron transfers occur in slow corrosion inside pipes and tanks.

Using field ORP data together with lab measurements gives operators clear feed control levers. By adjusting aeration, chemical dose, or contact time based on observed redox balance, plants can sustain stable performance and minimize energy waste while maintaining safe, compliant effluent quality.

Case-Style Scenarios: What Operators Watch and What They Tweak

While chemical equations describe theory, plant operators live by observation. Every reading, color shift, or pH swing tells a story about underlying oxidation reduction reactions. Knowing what those signals mean lets crews act before downtime starts.

Cooling Tower Biofouling Control

A slight ORP drop in a cooling-tower loop often means biofilm growth or depleted oxidant. Operators interpret this as an imbalance between oxidation and reduction processes. By increasing oxidant feed—typically chlorine or bromine—they restore the oxidized half that loses electrons and return the system to stable conditions. If ORP overshoots, the crew reduces dosage to avoid corrosion. This feedback loop keeps exchangers clean without wasting chemicals.

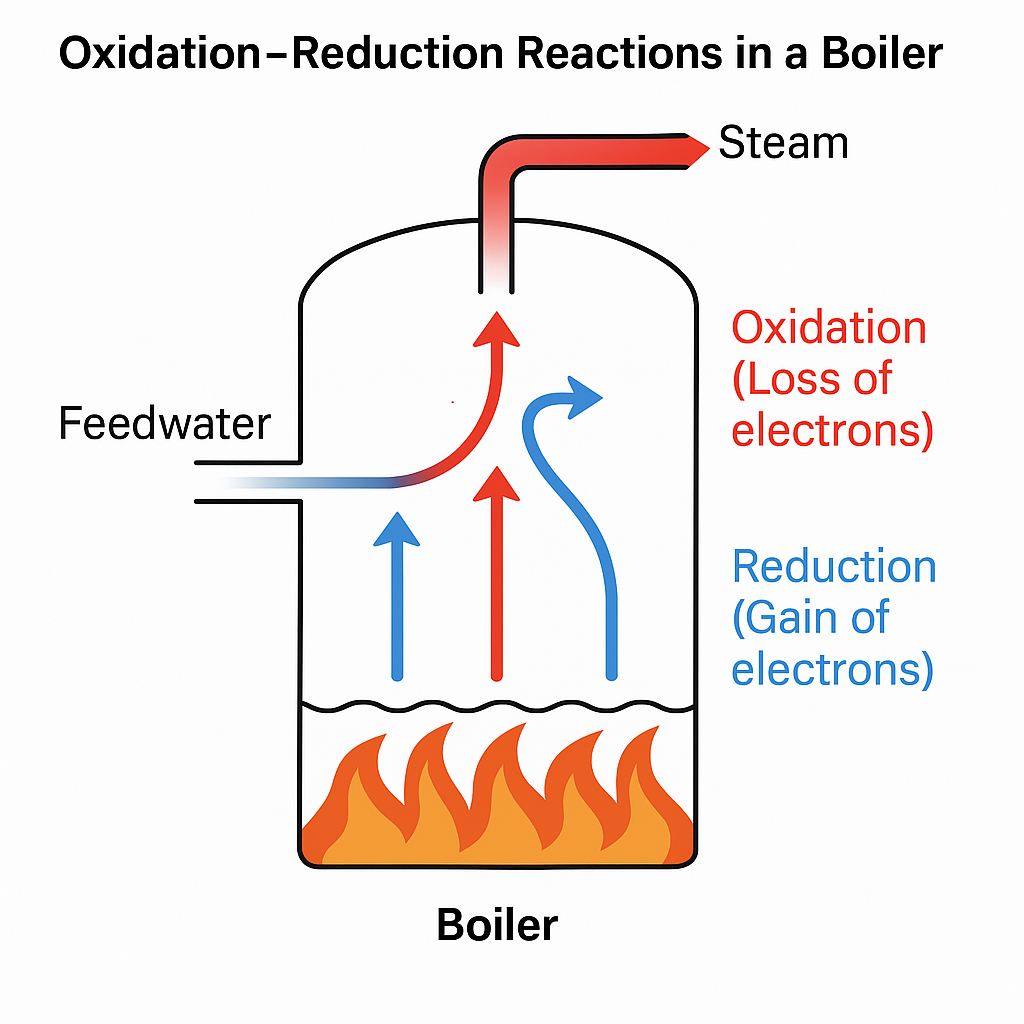

Boiler System Oxygen Scavenging

In boilers, even trace oxygen triggers corrosion. Reducing agents such as sulfite donate electrons to dissolved oxygen, forming sulfate and water. Here, the ion or molecule that donates electrons is intentionally consumed so the metal surface remains passive. When testing shows residual scavenger at target levels, staff know the oxidation and reduction occur in balance.

Wastewater Nutrient Removal

Biological reactors depend on alternating oxidizing and reducing zones. During nitrification, ammonia’s oxidation number increases as bacteria transfer electrons to oxygen. During denitrification, nitrate’s oxidation number decreases as it becomes nitrogen gas. Maintaining these alternating half-cycles ensures stable effluent and prevents energy waste from over-aeration.

Metals and pH Stability

When metal concentrations spike, technicians check whether the chemical species are in a soluble or precipitated oxidation state. If metals remain dissolved, an oxidizing agent is added; if solids form too quickly, a reducing agent tempers the reaction. Fine-tuning oxidation states this way prevents clogged filters and unplanned shutdowns.

Across these cases, the key to uptime is attention to electron flow. Every adjustment, from feed-pump speed to aeration rate, traces back to redox balance. By recognizing when the oxidized is the reducing or the reduced is the oxidizing component, operators convert chemistry into operational stability and measurable cost savings.

ETI Services: Redox Chemistry in Action

At ETI, chemistry meets reliability. Our water-treatment programs harness oxidation reduction reactions to protect assets, extend equipment life, and keep plants performing at full capacity. Through custom-blended formulations and technical support, we help facilities across Pennsylvania and Ohio control corrosion, scaling, and contamination before they disrupt operations.

Oxygen Scavenger for Boilers

Our team’s Oxygen Scavenger for Boilers solutions remove dissolved oxygen—the trigger for corrosion and pitting inside steam systems. Sulfite, DEHA, and erythorbate formulations react rapidly to neutralize oxygen, preventing oxidation of metal surfaces and improving heat-transfer efficiency. By stabilizing redox conditions, these treatments lower maintenance costs and reduce downtime caused by tube failure.

Rust Treatment for Boilers

Rust Treatment for Boilers programs use advanced reducing and passivating agents to dissolve existing rust while protecting metal surfaces from future oxidation. These formulations restore thermal efficiency, extend boiler life, and minimize costly shutdowns due to corrosion.

Heavy Metal Precipitation Solutions

For wastewater systems, Heavy Metal Precipitation Solutions apply targeted redox chemistry to convert toxic dissolved metals into stable, non-leachable precipitates. This selective oxidation-reduction process enables safe removal, regulatory compliance, and environmental protection.

Cooling Tower Chemical Treatments

Cooling Tower Chemical Treatments combine corrosion inhibitors, dispersants, and oxidizing biocides to maintain redox balance in recirculating systems. Controlled oxidation prevents biofouling, while passivating agents protect mixed metallurgy components under demanding conditions.

ETI backs every product with Technical Services and hands-on training through ETI Bootcamp and the CWT Certification Program. These initiatives ensure operators understand the science behind each reaction and can apply it safely and efficiently.

By aligning chemistry with performance goals, ETI turns oxidation-reduction management into measurable uptime and lasting system reliability.

Conclusion

Understanding and managing oxidation reduction reactions is more than academic chemistry; it’s a proven way to improve uptime, efficiency, and asset longevity. By controlling how electrons move through every stage of water and steam systems, operators prevent corrosion, scaling, and costly interruptions before they occur.

ETI helps facilities turn this chemistry into predictable performance through advanced treatment formulations, hands-on technical service, and operator training. From boiler protection to heavy-metal removal, ETI’s solutions keep oxidation and reduction in perfect balance—ensuring reliable operation across every industrial application.

Ready to optimize your plant’s performance?

Contact ETI today to learn how our tailored water treatment programs can reduce downtime and extend system life.

Frequently Asked Questions (FAQs)

What is an oxidation reduction redox reaction?

An oxidation reduction (redox) reaction is a chemical process involving the exchange of electrons between two substances. One species is oxidized (loses electrons) while the other is reduced (gains electrons). In ETI’s treatment programs, these reactions drive oxygen removal, corrosion protection, and contaminant precipitation.

How does hydrogen peroxide act in oxidation-reduction chemistry?

Hydrogen peroxide can function as both an oxidizing and a reducing agent. In boiler and wastewater applications, it decomposes into water and oxygen; the liberated oxygen supports oxidation of contaminants. Under certain conditions, it can also act as a mild reductant, enabling safe treatment where chlorine cannot be used.

What are disproportionation reactions, and are they relevant to ETI systems?

Disproportionation occurs when the same element is simultaneously oxidized and reduced in a single reaction. While uncommon in many industrial systems, they can arise with certain metal ions or during the decomposition of compounds like hydrogen peroxide. ETI’s chemical programs manage these reactions to maintain stability and prevent unwanted effects such as gas release or pH imbalance.

How does ETI evaluate oxidation states in treatment chemistry?

ETI specialists assess changes in oxidation state to verify that reactions proceed as intended. For example, metallic iron (Fe⁰) oxidizing to Fe²⁺ or Fe³⁺ indicates electron loss and confirms oxidation. Laboratory analysis tracks these shifts to ensure proper redox balance and performance.

Why are phosphorus and carbon important in oxidation-reduction reactions?

Phosphorus and carbon play central roles in both biological and chemical redox processes. Concepts such as the oxidation number of phosphorus are relevant to nutrient removal, while carbon is fundamental to organic oxidation, including BOD reduction and energy transfer in biological systems. ETI applies these principles when managing additives for wastewater and nutrient control.

What does “oxidized oxidation number 0” mean in corrosion control?

The phrase refers to an element, such as metallic iron, initially at an oxidation number of zero before corrosion starts. Upon exposure to oxidants like dissolved oxygen, it becomes oxidized and its oxidation number increases to a positive value. ETI’s corrosion inhibitors help prevent this transition, preserving metal integrity in boilers and cooling systems.

Are oxidation and reduction limited to metals, or do they occur in other reactions?

They occur broadly across chemistry and biology. Redox reactions also govern transformations in gases, organics, and microbial processes. Oxygen transfer between organic molecules and oxidants such as hydrogen peroxide follows the same electron-exchange principles seen in metal corrosion and chemical oxidation.