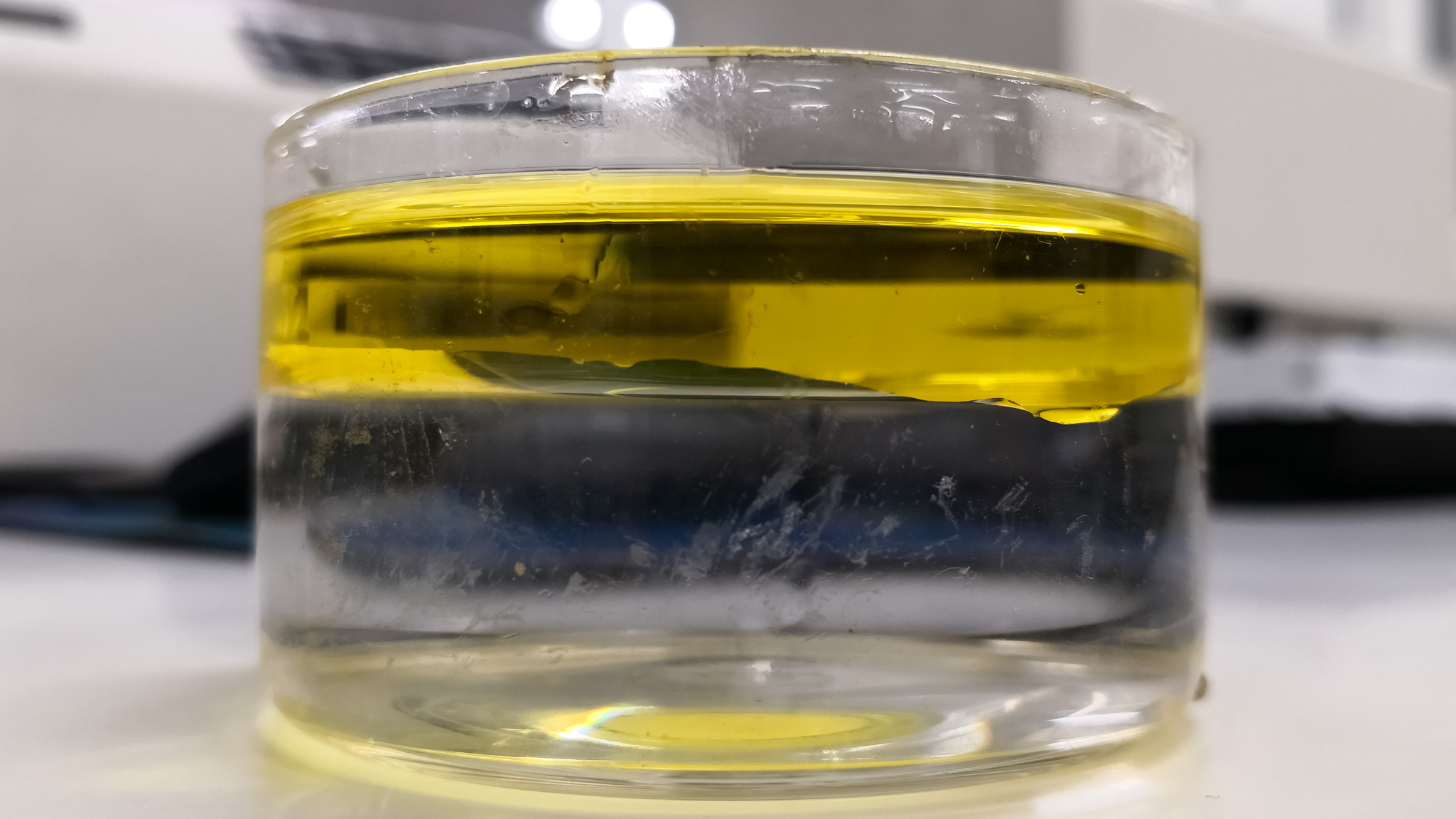

In industrial water and wastewater systems, emulsions often represent one of the most persistent and costly contamination challenges. Emulsions form when two immiscible liquids (typically oil and water) are mixed together in such a way that one becomes suspended within the other. Depending on the process, this may result in oil-in-water or water-in-oil emulsions, both of which are difficult to break without targeted chemical treatment.

These stable mixtures are common byproducts of operations in metal finishing, oil refining, food processing, chemical manufacturing, and even certain pharmaceutical and cosmetic production lines. Without proper treatment, emulsions can interfere with downstream filtration, overload biological systems, increase total suspended solids (TSS), and violate effluent discharge permits. Their impact is not just environmental but also operational: clogged membranes, fouled heat exchangers, and excess sludge production are all known consequences of poorly managed emulsions.

The key to solving these problems lies in effective water formulation. By engineering specific chemical formulas that target the physicochemical properties of the emulsion, water treatment professionals can restore system efficiency and meet regulatory demands. This article explores how formulation chemistry drives emulsion breaking success—focusing on the science, the strategies, and the formulation decisions – including active ingredient selection – that lead to high-performing, industry-ready solutions.

The Science of Emulsion Stability

Before breaking emulsions, it’s critical to understand what makes them stable in the first place. Emulsions are stabilized by a combination of physical and chemical forces that prevent the suspended phase from coalescing and separating. These forces are often strengthened by surfactants, which reduce surface tension and create a barrier around dispersed droplets, preventing them from merging.

Several specific properties contribute to emulsion stability:

- Particle size: Smaller oil droplets have a larger surface area relative to volume, making them more resistant to gravitational separation.

- Zeta potential: The electrical charge on particle surfaces affects how strongly droplets repel each other.

- Viscosity: Higher viscosity increases emulsion stability by slowing droplet movement and reducing collision frequency.

- Polarity and solubility: The polarity of both the dispersed and continuous phases influences emulsification behavior, especially when dealing with polar compounds or nonpolar solvents.

Surfactants or emulsifiers are key chemical agents in maintaining emulsion stability. These molecules often have hydrophilic and hydrophobic ends, allowing them to bridge incompatible phases and stabilize the emulsion. However, the desired properties that make emulsions stable also make them difficult to treat in wastewater processes.

To design effective treatment, stability testing is often conducted in the lab to evaluate how emulsions respond to pH adjustment, temperature changes, and chemical dosing. This process reveals the desired effects of different breaking strategies and helps select the right active ingredients and final product.

Water Formulation Strategies for Breaking Emulsions

The success of any emulsion-breaking program depends on the strength and precision of its chemical formula, active ingredient, and intended use. Unlike off-the-shelf treatments, effective demulsifiers are carefully engineered blends – typically by a formulations chemist – that account for the chemistry of the emulsion, the properties of the wastewater, and the physical characteristics of the treatment system.

Key Types of Emulsion Breakers

- Surfactant-Based Formulations

These rely on compounds that displace or neutralize the emulsifying agents within the system. By disrupting the interface between oil and water, they allow droplets to coalesce and separate. - Solvent-Based Formulations

Often used in hydrocarbon-rich systems, solvents modify the solubility balance, allowing oil and water phases to separate under gravity or with minimal mechanical input. These are typically used in systems with high levels of stable emulsifiers or low temperatures. - Polymeric Formulations

These substance composed of high-molecular-weight compounds enhance floc formation and improve separation in downstream processes such as dissolved air flotation (DAF) or settling basins.

Key Components in Water Formulation Chemistry

The art of formulation chemistry lies in balancing different chemical agents to achieve effective separation without disrupting system stability. This includes:

- Wetting agents: Reduce interfacial tension to help oil droplets combine and rise or settle.

- Nonpolar solvents: Dissolve or thin emulsified oil, making it easier to separate.

- Chelating agents: Bind to metals that may stabilize emulsions, reducing their influence on system chemistry.

- Drying agents: Remove water from oil-rich emulsions or enhance water removal in oil-contaminated streams.

- Other components: May include pH buffers, dispersants, and compatibility stabilizers to fine-tune performance.

Each water formulation is designed to accommodate not just the chemical makeup of the emulsion but also the physical environment. Temperature, flow rate, turbulence, and retention time all influence which components will work best.

Matching Water Formulation to Emulsion Type

There is no one-size-fits-all product in emulsion breaking. The specializing chemist must evaluate whether the emulsion is stabilized by surfactants, fine solids, metal ions, or temperature and select ingredients accordingly. For example:

- Food & beverage plants may require low-toxicity, biodegradable agents.

- Petrochemical facilities often demand high-performance solvent-based products that handle crude or lubricant emulsions.

- Metalworking operations might need pH-sensitive formulations that do not destabilize downstream coagulants or flocculants.

Successful emulsion breaking requires more than just selecting an existing formulation. It demands a purpose-built solution with the right blend of active ingredients, chosen for both their individual function and their combined impact on the final products’ emulsion structure.

Learn more on our blog: Selecting the Right Polymer Flocculant for Wastewater Treatment

Supporting Chemical Agents in Emulsion Breaking Water Formulations

These ingredients are not always the focus of a product label, but they play a critical role in making a chemical formula perform under variable field conditions:

- Hydrogen Peroxide

In some applications, controlled oxidation helps break down organic emulsifiers or disrupt surface-active materials. Hydrogen peroxide is used for its oxidative strength and environmental compatibility. - Titanium Dioxide and Zinc Oxide

Though better known for use in coatings and sunscreens, these metal oxides can be leveraged in emulsion treatment for their photocatalytic or destabilizing properties. They are also used in sludge conditioning in specific wastewater applications. - Polymer Resins

These long-chain molecules can act as floc-assisting additives, especially when emulsions are stabilized by fine solids. Their function is to help coalesce destabilized droplets into larger masses that are easier to separate by gravity or flotation. - Dye Intermediates and Color Stabilizers

Certain industrial waste streams, such as textile or chemical manufacturing, may contain emulsified oils with pigment or dye components. Specialized intermediates can be added to chemical formulas to address visual clarity requirements or ensure compatibility with cleaning products used later in the treatment train. - Oxygenated Additives

Used to promote oxidative separation or alter the solubility profile of hydrocarbons. These additives are common in blends designed for oily wastewater with high chemical oxygen demand (COD).

Optimizing for System Compatibility

Many of these other components are included not just for breaking emulsions but for improving system compatibility. A good example is the use of polymer-enhanced emulsion breakers in systems where dissolved air flotation (DAF) is used. These agents promote uniform floc formation and increase floatable solids recovery.

Similarly, oxidation-promoting agents must be carefully dosed to avoid damaging downstream biological systems or generating unwanted byproducts. The balance between separation performance and system stability is where the true challenge of water formulation chemistry lies.

In short, the most effective emulsion-breaking strategies are supported by formulation chemistry that extends beyond the core surfactant. Understanding how these agents interact makes it possible to tailor treatments that work efficiently without introducing new treatment complications.

Read Wastewater Purification System: Microbial Testing Explained to learn more on microbial contamination.

Regulatory and Performance Considerations

A high-performing chemical formula must do more than just separate oil from water. It must also meet a host of operational and regulatory requirements that vary by industry, application, and geography. Whether targeting wastewater from industrial cooling systems, process washdowns, or manufacturing effluent, every emulsion breaker must be developed and deployed with compliance, safety, and long-term usability in mind.

Regulatory Requirements

In the United States, the Environmental Protection Agency (EPA) sets discharge limits for oil and grease, total suspended solids (TSS), and chemical oxygen demand (COD). Many emulsion breakers, especially those used in oil-water separation, fall under EPA scrutiny for their toxicity, biodegradability, and compatibility with downstream treatment systems.

A successful final product must:

- Comply with local and federal wastewater discharge permits

- Avoid introducing regulated contaminants or persistent residuals

- Work within systems that include biological treatment, DAF, or tertiary filtration

- Support pollution prevention goals under environmental health and safety programs

Shelf Life and Microbial Stability

Many emulsion breakers include water-based components or organic solvents, both of which can be susceptible to microbial growth if improperly preserved. To prevent microbial growth, preservatives or antimicrobial agents may be introduced into the water formulation. This ensures the product remains active, reliable, and creates the desired effects through transport, storage, and deployment.

In addition, shelf life is influenced by:

- Container type and seal integrity

- Temperature exposure during shipping or storage

- Interaction between active ingredients and carrier fluids

Proper stability testing ensures the final product maintains its intended properties from batch to batch and over time.

Application-Specific Performance

Every emulsion breaker must be validated for the conditions in which it will operate. This includes:

- Low concentrations for sensitive systems such as food processing

- Higher concentrations for tough emulsions in petrochemical or metal finishing plants

- Compatibility with cleaning agents or pre-existing chemistries

- Consistent field performance across changing influent profiles

In water treatment, reliability is critical. That’s why performance metrics are often built into formulation specifications, including separation time, residual oil content, and compatibility with downstream filtration media.

Industry Examples: Where Water Formulations Differ

Industrial sectors generate widely different types of emulsified wastewater depending on the materials involved, processing methods, and intended discharge or reuse goals. A key part of successful chemical formulation is tailoring the ingredients and concentrations to suit the application.

Food and Beverage Processing

Facilities in the food industry often produce oil-in-water emulsions stabilized by fats, proteins, and surfactants. The emulsion breakers used here must meet food safety standards and avoid interfering with biological treatment systems. That means:

- Low concentrations of actives to protect microbes

- Biodegradable ingredients

- Minimal odor and no strong perfumes

The intended use often includes discharge to municipal systems or water reuse, which requires clean separation without introducing harsh chemicals.

Petrochemical and Refining

At the opposite end of the spectrum are oil refineries and fuel handling operations. These facilities produce highly stable water-in-oil emulsions containing hydrocarbons, additives, and sometimes heavy metals. Formulations here demand:

- Higher concentrations of solvent-based or polymeric agents

- Resistance to extreme temperatures and pH ranges

- Compatibility with secondary systems such as DAF or hydrocyclones

The emulsions are often resistant to gravity separation, requiring new technology or hybrid chemical-mechanical approaches to break.

Metalworking and Manufacturing

Operations involving cutting fluids, lubricants, and cleaning processes generate emulsions that are often stabilized by surfactants and fine particulates. Here, the variation between existing formulations of fluids means treatment must be flexible. Emulsion breakers in these systems are usually:

- Tuned for charge compatibility with metal ions or salts

- Designed to separate emulsions formed by recycled or reused process fluids

- Integrated into cleaning product programs or discharge permits

Cosmetic and Pharmaceutical Production

In applications like the cosmetic industry, emulsions may contain emulsifiers, melanin compounds, fragrances, and preservatives. In these cases, the priority is often eliminating visual discoloration, surface foam, or oily residue. Formulations must also address sensory appeal and avoid disrupting sensitive wastewater equipment.

ETI’s Water Formulation Expertise in Emulsion Breaking

At ETI, we understand that breaking emulsions is not a matter of choosing a generic chemical formula. It’s about engineering a solution that works with your system, your waste stream, and your compliance requirements. With decades of experience in chemical formulation for water treatment, our team develops industry-specific strategies that deliver measurable performance and long-term reliability.

Custom Chemistry, Proven Separation

Our emulsion-breaking programs are built on a foundation of:

- Field-validated water formulations tested for separation speed, compatibility, and sludge characteristics

- Tailored blends of surfactants, solvents, polymer resins, and chelating agents to address each emulsion’s root cause

- Compatibility with both conventional and advanced treatment systems such as DAF, clarifiers, and membrane processes

Whether you are treating oily washdowns in a food facility or dealing with complex emulsions in petrochemical wastewater, ETI provides scalable water formulations and chemical analysis optimized for your intended use.

Anchored in a Full-Service Approach

ETI doesn’t just supply products, we deliver comprehensive treatment support. Our process includes:

- Oil Treatment Solutions

We provide advanced oil-water separation agents and emulsion breakers that support clean discharge and protect downstream systems. Learn more on our Oil Treatment page. - Coagulation & Flocculation Support

ETI’s Advanced Coagulants and Advanced Flocculants are used alongside emulsion breakers to enhance settling and reduce oil carryover in industrial effluent. - Formulation Refinement and Monitoring

We work directly with water treatment companies to evaluate emulsion characteristics and adjust treatment strategies based on seasonal or operational changes.

Our success is rooted in understanding how formulated products behave in real-world systems. From lab-scale jar testing to full-scale field trials, ETI ensures that every emulsion breaker meets its performance targets while staying within regulatory and safety parameters. Our commitment to consistent quality, regulatory compliance, and long-term technical support makes us a trusted partner to water treatment professionals across industries.

Water Formulation Challenges and Innovation Outlook

Even the most carefully developed chemical formulation can encounter real-world challenges once deployed in the field. These are some of the common formulation challenges you might encounter:

- Variable Influent Quality

Many industrial facilities experience changes in emulsion composition due to shifts in production, maintenance schedules, or cleaning protocols. A formulation that works one month may require adjustment the next. - Scaling from Lab to Field

A water formulation that succeeds during lab-scale rigorous testing may behave differently under real-world conditions due to retention time, flow dynamics, or mixing inefficiencies. - Chemical Interactions

Unexpected reactions with coagulants, flocculants, or existing wastewater chemistry can reduce the effectiveness of even a well-designed product. - Shelf Life and Packaging Constraints

Maintaining product stability without sacrificing performance is especially important in large-scale operations or remote sites with infrequent deliveries.

Where Innovation Is Headed

To address these challenges, water formulation chemists are exploring new active ingredients, delivery methods, and technologies. Innovations include:

- Bio-based emulsifiers and solvents for safer, more sustainable formulations

- Smart delivery systems that release active agents based on pH or contaminant levels

- Enhanced chemical changes modeling using AI to predict emulsion behavior

- Additives that offer both separation performance and sludge conditioning

For manufacturers and water treatment companies, the future of emulsion treatment lies in adaptability. By building flexibility into product design and leveraging field feedback, formulators can ensure better outcomes across various industries with evolving treatment needs.

Let’s Talk

If your facility or treatment program is facing challenges with oil separation or persistent emulsions, ETI can help you design a formulation strategy that aligns with your goals. Our team supports water treatment professionals across industries with custom chemistry, regulatory alignment, and field-tested solutions.

Let’s talk about how to make your next emulsion-breaking program more efficient, compliant, and cost-effective.

Frequently Asked Questions (FAQs)

1. What role does methanol play in emulsion treatment?

Methanol is sometimes used as a co-solvent or polarity adjuster in formulations to help dissolve stabilizers or modify the emulsification behavior in solvent-rich systems.

2. Can emulsion breakers be used in systems with air injection?

Yes, air injection systems like DAF can be paired with emulsion breakers, but the chemical formulation must be compatible with aeration to prevent foam or carryover.

3. What chemical agents are most effective for difficult emulsions?

The most effective chemical agents vary by emulsion type, but formulations often include solvents, surfactants, and chelating compounds to target different emulsifier mechanisms.

4. How do water formulation strategies differ for agricultural products?

In agriculture, water formulation strategies often consider environmental runoff risks, requiring low-toxicity agents and targeting pesticide formulations with specific degradation profiles.

5. Can agents used in emulsion breakers affect microbial growth in wastewater systems?

Yes. Some chemical agents may inhibit or encourage microbial growth, so it is important to choose formulations that prevent negative biological impacts in downstream treatment.